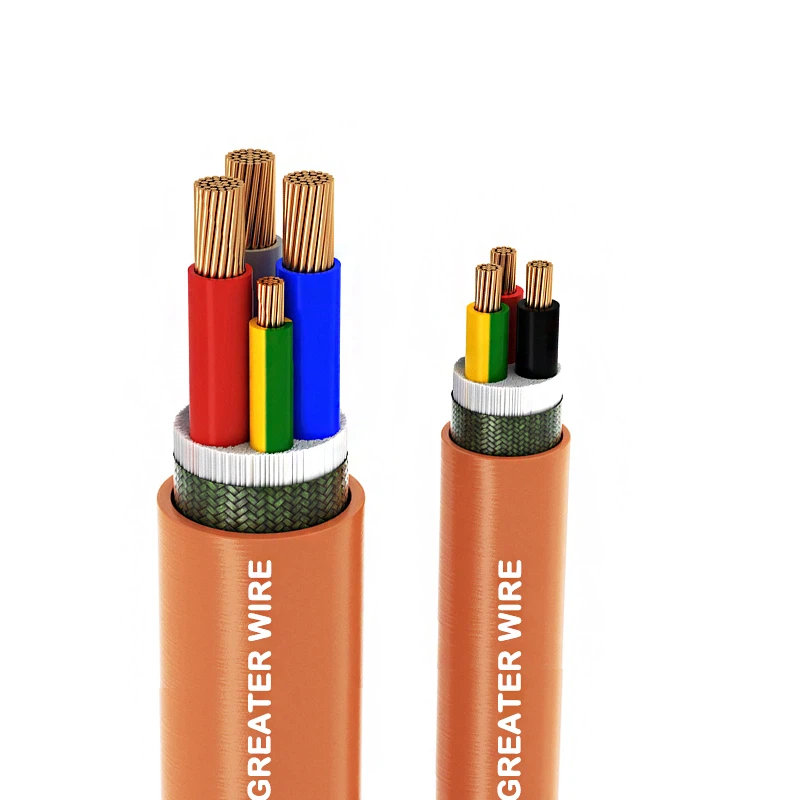

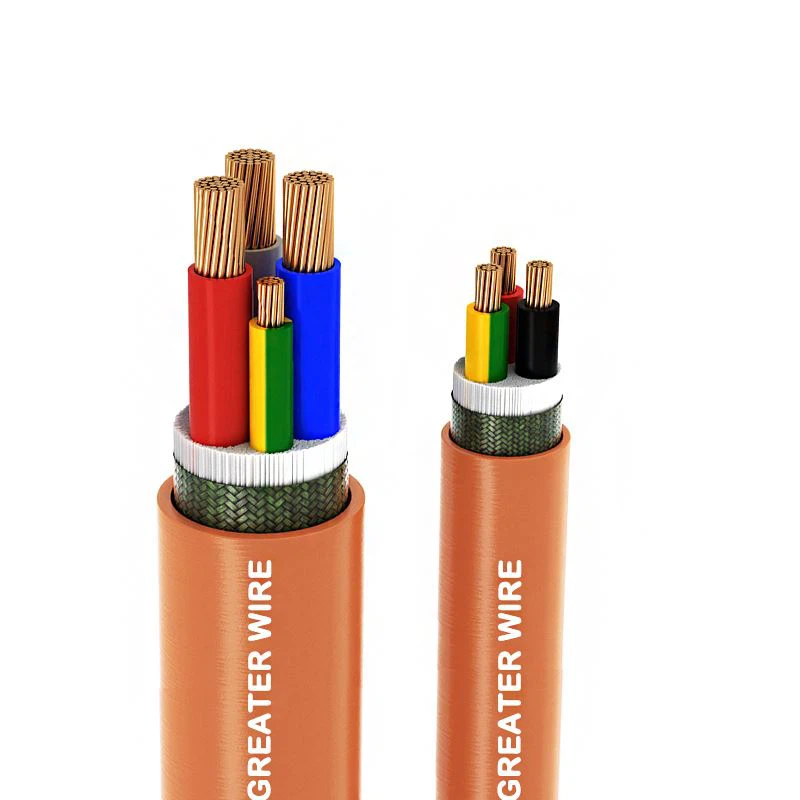

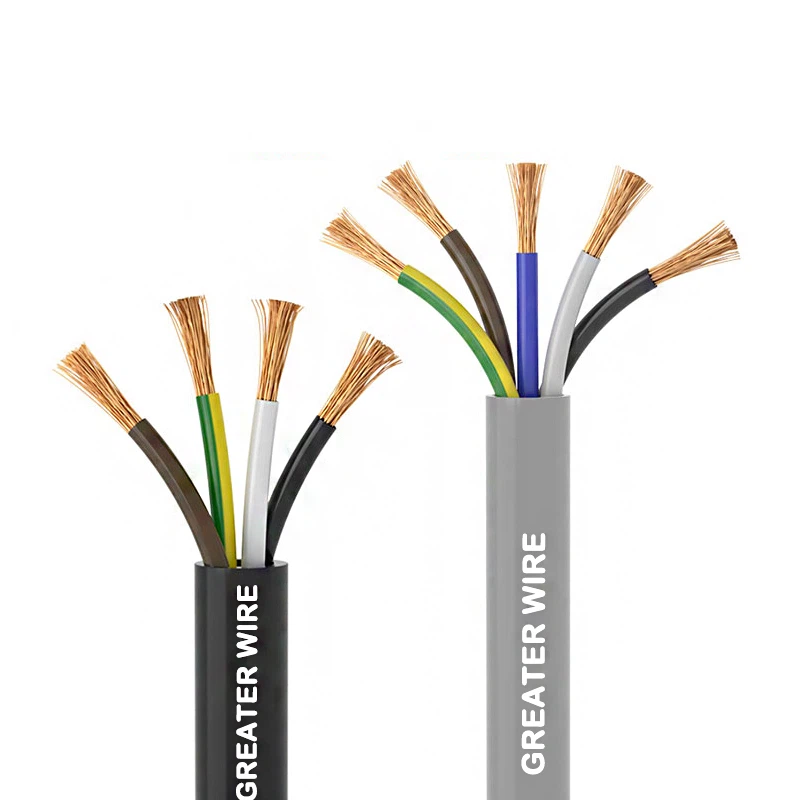

14/2 14/4 electrical wire consists of a multi-strand copper core and a double-layer insulation sheath, with excellent oil resistance, water resistance, chemical corrosion resistance and weather resistance. It has a rated voltage of 600V and an operating temperature range of typically -40°C to 90°C. The 14 AWG wire size makes it perform well in devices with lower current load requirements, ensuring the safety and stability of power transmission.

14/2 soow cord represents the wire gauge and number of cores in the cable. 14 means that the standard diameter of each wire is 14 AWG (American Wire Gauge), and 2 means that there are 2 wires in the cable. Usually this cable has two wires, one for live and one for neutral, which is suitable for simple single-phase power transmission.

14/4 soow cord means that there are 4 wires in each cable, and the specification of each wire is 14 AWG. Usually this cable contains a ground wire in addition to the common live and neutral wires, or is suitable for systems that require more power or control signals.

Application

14/2 SOOW wire are generally used for lower current transmission, suitable for control circuits, power supplies for low-voltage equipment, lamps, low-power equipment, etc. Common application scenarios include: lighting equipment connection. Power cords for small power tools or household appliances. Mobile electrical equipment or machines. Temporary power connections in outdoor or humid environments.

14/4 SOOW wire are suitable for equipment that requires more electrical connections, such as: equipment that requires multi-channel control signal transmission; temporary power systems, mobile power devices; control systems for industrial machines and equipment; can be used to connect multiple power sources or equipment, such as multiple power tools, mobile mechanical equipment, etc.

Certification

GREATER's SOOW cord and their range of products have been UL certified, with certification number E543176, ensuring they meet stringent safety standards and electrical performance requirements. The certification indicates that these cables are resistant to oil, water, UV rays and abrasion, and can operate stably in high and low temperatures and other extreme conditions, ensuring user safety and equipment reliability.

In addition to SOOW cables, UL certification also covers several similar models, including: S, SJ, SJO, SJOO, SJOOW, SJOW, SO, SOO, SOW, SJT, ST, STW, SVT and SJTW. All of these models have passed UL's strict certification, guaranteeing lasting reliability and safety in their respective use environments.

Package

Factory

GREATER is a professional SOOW cable manufacturer with 30 years of rich experience in cable manufacturing. As a leading cable manufacturer in the industry, GREATER has a research and development team of 20+ technicians, focusing on innovation and technology improvement to ensure that products meet global safety standards.

The company is equipped with 15 sets of advanced cable extrusion production lines with efficient and precise production capabilities to meet large-scale production and high-standard customization needs.

At present, GREATER's soow electrical wire have been exported to 89 countries, and its services cover 180+ countries and regions around the world, making it a trusted cable supplier for global customers.

Case

Partner

FAQ

Q: Is SOOW wire waterproof?

Q: What are the uses permitted for SOOW cord?

Q: What is the amp rating of 14 4 soow cord?

However, it should be noted that 14/4 SOOW is a four-conductor cable with a 14 AWG specification, so the load of each conductor can be 15 amps, but the specific load of each conductor depends on the power source used and the actual layout of the cable.

Hot Tags: 14/2 14/4 soow electrical Cable 600v, China 14/2 14/4 soow electrical Cable 600v manufacturers, suppliers, factory, xlpe power cable, cul standard rw75 rw90 rwu75 rwu90 cable, single core building cable, Solar Cable 1500V H1Z2Z2 K TUV UL EN 50618 Solar PV Cable, 110 elastomer cables, SPT 1 SPT 2 Wire

|

Size

|

Noof

conductor

|

Conductor

strand

|

Nominal

insulation

thickness

|

Nominal

jacket

thickness

|

Nominal

overall

diameter

|

Weight

|

Ampacity

at30°C

in air

|

|||

|

Inches

|

mm

|

Inches

|

mm

|

Inches

|

mm

|

lbs/1000ft

|

A

|

|||

| 18 | 2 | 16/30 | 0.030 | 0.76 | 0.060 | 1.52 | 0.34 | 8.6 | 63 | 10 |

| 18 | 3 | 16/30 | 0.030 | 0.76 | 0.060 | 1.52 | 0.36 | 9.1 | 74 | 10 |

| 18 | 4 | 16/30 | 0.030 | 0.76 | 0.060 | 1.52 | 0.39 | 9.8 | 87 | 7 |

| 18 | 5 | 16/30 | 0.030 | 0.76 | 0.080 | 2.03 | 0.46 | 11.7 | 123 | 5.6 |

| 18 | 6 | 16/30 | 0.030 | 0.76 | 0.080 | 2.03 | 0.48 | 12.3 | 131 | 5.6 |

| 18 | 7 | 16/30 | 0.030 | 0.76 | 0.080 | 2.03 | 0.48 | 12.3 | 134 | 5.6 |

| 18 | 8 | 16/30 | 0.030 | 0.76 | 0.080 | 2.03 | 0.52 | 13.1 | 151 | 4.9 |

| 18 | 10 | 16/30 | 0.030 | 0.76 | 0.080 | 2.03 | 0.59 | 15.0 | 180 | 4.9 |

| 18 | 12 | 16/30 | 0.030 | 0.76 | 0.080 | 2.03 | 0.61 | 15.4 | 202 | 3.5 |

| 18 | 14 | 16/30 | 0.030 | 0.76 | 0.095 | 2.41 | 0.66 | 16.9 | 246 | 3.5 |

| 18 | 16 | 16/30 | 0.030 | 0.76 | 0.095 | 2.41 | 0.69 | 17.6 | 274 | 3.5 |

| 18 | 18 | 16/30 | 0.030 | 0.76 | 0.095 | 2.41 | 0.73 | 18.5 | 303 | 3.5 |

| 18 | 20 | 16/30 | 0.030 | 0.76 | 0.095 | 2.41 | 0.76 | 19.3 | 333 | 3.5 |

| 18 | 22 | 16/30 | 0.030 | 0.76 | 0.095 | 2.41 | 0.83 | 21.2 | 357 | 3.2 |

| 18 | 24 | 16/30 | 0.030 | 0.76 | 0.095 | 2.41 | 0.83 | 21.2 | 376 | 3.2 |

| 18 | 26 | 16/30 | 0.030 | 0.76 | 0.095 | 2.41 | 0.85 | 21.7 | 401 | 3.2 |

| 18 | 27 | 16/30 | 0.030 | 0.76 | 0.095 | 2.41 | 0.85 | 21.9 | 409 | 3.2 |

| 18 | 30 | 16/30 | 0.030 | 0.76 | 0.110 | 2.79 | 0.91 | 23.0 | 470 | 3.2 |

| 18 | 36 | 16/30 | 0.030 | 0.76 | 0.110 | 2.79 | 0.97 | 24.7 | 551 | 2.8 |

| 18 | 39 | 16/30 | 0.030 | 0.76 | 0.110 | 2.79 | 1.04 | 26.3 | 604 | 2.8 |

| 18 | 44 | 16/30 | 0.030 | 0.76 | 0.110 | 2.79 | 1.08 | 27.4 | 647 | 2.5 |

| 18 | 52 | 16/30 | 0.030 | 0.76 | 0.110 | 2.79 | 1.12 | 28.5 | 735 | 2.5 |

| 18 | 60 | 16/30 | 0.030 | 0.76 | 0.125 | 3.18 | 1.22 | 30.9 | 870 | 2.5 |

| 16 | 2 | 26/30 | 0.030 | 0.76 | 0.060 | 1.52 | 0.37 | 9.3 | 76 | 13 |

| 16 | 3 | 26/30 | 0.030 | 0.76 | 0.060 | 1.52 | 0.39 | 10.1 | 90 | 13 |

| 16 | 4 | 26/30 | 0.030 | 0.76 | 0.060 | 1.52 | 0.42 | 10.6 | 107 | 10 |

| 16 | 5 | 26/30 | 0.030 | 0.76 | 0.080 | 2.03 | 0.49 | 12.5 | 149 | 8 |

| 16 | 6 | 26/30 | 0.030 | 0.76 | 0.080 | 2.03 | 0.53 | 13.4 | 165 | 8 |

| 16 | 7 | 26/30 | 0.030 | 0.76 | 0.080 | 2.03 | 0.53 | 13.4 | 170 | 8 |

| 16 | 8 | 26/30 | 0.030 | 0.76 | 0.080 | 2.03 | 0.56 | 14.3 | 193 | 7 |

| 16 | 9 | 26/30 | 0.030 | 0.76 | 0.095 | 2.41 | 0.65 | 16.5 | 238 | 7 |

| 16 | 10 | 26/30 | 0.030 | 0.76 | 0.095 | 2.41 | 0.68 | 17.2 | 251 | 7 |

| 16 | 12 | 26/30 | 0.030 | 0.76 | 0.095 | 2.41 | 0.70 | 17.7 | 282 | 5 |

| 16 | 14 | 26/30 | 0.030 | 0.76 | 0.095 | 2.41 | 0.73 | 18.5 | 316 | 5 |

| 16 | 16 | 26/30 | 0.030 | 0.76 | 0.095 | 2.41 | 0.76 | 19.4 | 354 | 5 |

| 16 | 18 | 26/30 | 0.030 | 0.76 | 0.095 | 2.41 | 0.80 | 20.3 | 393 | 5 |

| 16 | 20 | 26/30 | 0.030 | 0.76 | 0.095 | 2.41 | 0.84 | 21.2 | 434 | 5 |

| 16 | 22 | 26/30 | 0.030 | 0.76 | 0.095 | 2.41 | 0.92 | 23.4 | 464 | 4.5 |

| 16 | 24 | 26/30 | 0.030 | 0.76 | 0.110 | 2.79 | 0.95 | 24.1 | 520 | 4.5 |

| 16 | 27 | 26/30 | 0.030 | 0.76 | 0.110 | 2.79 | 0.97 | 24.6 | 566 | 4.5 |

| 16 | 30 | 26/30 | 0.030 | 0.76 | 0.110 | 2.79 | 1.00 | 25.4 | 615 | 4.5 |

| 16 | 36 | 26/30 | 0.030 | 0.76 | 0.110 | 2.79 | 1.07 | 27.3 | 724 | 4 |

| 16 | 37 | 26/30 | 0.030 | 0.76 | 0.110 | 2.79 | 1.07 | 27.3 | 730 | 4 |

| 16 | 39 | 26/30 | 0.030 | 0.76 | 0.110 | 2.79 | 1.15 | 29.1 | 795 | 4 |

| 16 | 40 | 26/30 | 0.030 | 0.76 | 0.125 | 3.18 | 1.18 | 29.9 | 843 | 4 |

| 16 | 44 | 26/30 | 0.030 | 0.76 | 0.125 | 3.18 | 1.23 | 31.1 | 891 | 3.5 |

| 16 | 52 | 26/30 | 0.030 | 0.76 | 0.125 | 3.18 | 1.28 | 32.4 | 1016 | 3.5 |

| 16 | 60 | 26/30 | 0.030 | 0.76 | 0.125 | 3.18 | 1.35 | 34.2 | 1154 | 3.5 |

| 14 | 2 | 41/30 | 0.045 | 1.14 | 0.080 | 2.03 | 0.50 | 12.6 | 137 | 18 |

| 14 | 3 | 41/30 | 0.045 | 1.14 | 0.080 | 2.03 | 0.52 | 13.3 | 161 | 18 |

| 14 | 4 | 41/30 | 0.045 | 1.14 | 0.080 | 2.03 | 0.57 | 14.4 | 192 | 15 |

| 14 | 5 | 41/30 | 0.045 | 1.14 | 0.095 | 2.41 | 0.64 | 16.4 | 251 | 12 |

| 14 | 6 | 41/30 | 0.045 | 1.14 | 0.095 | 2.41 | 0.69 | 17.6 | 277 | 12 |

| 14 | 7 | 41/30 | 0.045 | 1.14 | 0.095 | 2.41 | 0.69 | 17.6 | 285 | 12 |

| 14 | 8 | 41/30 | 0.045 | 1.14 | 0.095 | 2.41 | 0.74 | 18.9 | 324 | 10.5 |

| 14 | 9 | 41/30 | 0.045 | 1.14 | 0.095 | 2.41 | 0.86 | 21.9 | 367 | 10.5 |

| 14 | 10 | 41/30 | 0.045 | 1.14 | 0.095 | 2.41 | 0.86 | 21.9 | 388 | 10.5 |

| 14 | 12 | 41/30 | 0.045 | 1.14 | 0.095 | 2.41 | 0.89 | 22.5 | 441 | 7.5 |

| 14 | 14 | 41/30 | 0.045 | 1.14 | 0.095 | 2.41 | 0.93 | 23.6 | 498 | 7.5 |

| 14 | 16 | 41/30 | 0.045 | 1.14 | 0.095 | 2.41 | 0.98 | 24.8 | 563 | 7.5 |

| 14 | 18 | 41/30 | 0.045 | 1.14 | 0.110 | 2.79 | 1.06 | 26.9 | 660 | 7.5 |

| 14 | 20 | 41/30 | 0.045 | 1.14 | 0.110 | 2.79 | 1.11 | 28.1 | 730 | 7.5 |

| 14 | 24 | 41/30 | 0.045 | 1.14 | 0.110 | 2.79 | 1.22 | 31.1 | 828 | 6.8 |

| 14 | 30 | 41/30 | 0.045 | 1.14 | 0.125 | 3.18 | 1.32 | 33.6 | 1027 | 6.8 |

| 14 | 36 | 41/30 | 0.045 | 1.14 | 0.125 | 3.18 | 1.42 | 36.2 | 1215 | 6.0 |

| 14 | 37 | 41/30 | 0.045 | 1.14 | 0.125 | 3.18 | 1.42 | 36.2 | 1224 | 6.0 |

| 14 | 44 | 41/30 | 0.045 | 1.14 | 0.125 | 3.18 | 1.59 | 40.4 | 1437 | 5.3 |

| 14 | 52 | 41/30 | 0.045 | 1.14 | 0.125 | 3.18 | 1.66 | 42.2 | 1648 | 5.3 |

| 14 | 60 | 41/30 | 0.045 | 1.14 | 0.140 | 3.56 | 1.79 | 45.5 | 1939 | 5.3 |

| 12 | 2 | 65/30 | 0.045 | 1.14 | 0.095 | 2.41 | 0.57 | 14.4 | 184 | 25 |

| 12 | 3 | 65/30 | 0.045 | 1.14 | 0.095 | 2.41 | 0.59 | 15.2 | 217 | 25 |

| 12 | 4 | 65/30 | 0.045 | 1.14 | 0.095 | 2.41 | 0.64 | 16.5 | 261 | 20 |

| 12 | 5 | 65/30 | 0.045 | 1.14 | 0.095 | 2.41 | 0.70 | 17.8 | 319 | 16 |

| 12 | 6 | 65/30 | 0.045 | 1.14 | 0.095 | 2.41 | 0.74 | 18.8 | 344 | 16 |

| 12 | 7 | 65/30 | 0.045 | 1.14 | 0.095 | 2.41 | 0.74 | 18.8 | 358 | 16 |

| 12 | 8 | 65/30 | 0.045 | 1.14 | 0.095 | 2.41 | 0.80 | 20.2 | 408 | 14 |

| 12 | 9 | 65/30 | 0.045 | 1.14 | 0.095 | 2.41 | 0.92 | 23.5 | 461 | 14 |

| 12 | 10 | 65/30 | 0.045 | 1.14 | 0.110 | 2.79 | 0.95 | 24.2 | 519 | 14 |

| 12 | 12 | 65/30 | 0.045 | 1.14 | 0.110 | 2.79 | 0.98 | 24.9 | 591 | 10 |

| 12 | 14 | 65/30 | 0.045 | 1.14 | 0.110 | 2.79 | 1.03 | 26.1 | 668 | 10 |

| 12 | 16 | 65/30 | 0.045 | 1.14 | 0.110 | 2.79 | 1.08 | 27.5 | 755 | 10 |

| 12 | 18 | 65/30 | 0.045 | 1.14 | 0.125 | 3.18 | 1.17 | 29.6 | 878 | 10 |

| 12 | 20 | 65/30 | 0.045 | 1.14 | 0.125 | 3.18 | 1.22 | 31.0 | 971 | 10 |

| 12 | 24 | 65/30 | 0.045 | 1.14 | 0.125 | 3.18 | 1.35 | 34.3 | 1106 | 9 |

| 12 | 26 | 65/30 | 0.045 | 1.14 | 0.125 | 3.18 | 1.38 | 35.0 | 1180 | 9 |

| 12 | 30 | 65/30 | 0.045 | 1.14 | 0.125 | 3.18 | 1.43 | 36.3 | 1327 | 9 |

| 12 | 36 | 65/30 | 0.045 | 1.14 | 0.125 | 3.18 | 1.53 | 39.0 | 1573 | 8 |

| 12 | 37 | 65/30 | 0.045 | 1.14 | 0.125 | 3.18 | 1.53 | 39.0 | 1588 | 8 |

| 12 | 44 | 65/30 | 0.045 | 1.14 | 0.125 | 3.18 | 1.72 | 43.6 | 1868 | 7 |

| 12 | 60 | 65/30 | 0.045 | 1.14 | 0.140 | 3.56 | 1.90 | 48.3 | 2467 | 7 |

| 10 | 2 | 103/30 | 0.045 | 1.14 | 0.095 | 2.41 | 0.62 | 15.6 | 230 | 30 |

| 10 | 3 | 103/30 | 0.045 | 1.14 | 0.095 | 2.41 | 0.65 | 16.5 | 281 | 30 |

| 10 | 4 | 103/30 | 0.045 | 1.14 | 0.095 | 2.41 | 0.70 | 17.8 | 336 | 25 |

| 10 | 5 | 103/30 | 0.045 | 1.14 | 0.095 | 2.41 | 0.76 | 19.3 | 409 | 20 |

| 10 | 6 | 103/30 | 0.045 | 1.14 | 0.095 | 2.41 | 0.82 | 20.7 | 452 | 20 |

| 10 | 7 | 103/30 | 0.045 | 1.14 | 0.095 | 2.41 | 0.82 | 20.7 | 474 | 20 |

| 10 | 8 | 103/30 | 0.045 | 1.14 | 0.095 | 2.41 | 0.88 | 22.3 | 541 | 17.5 |

| 10 | 10 | 103/30 | 0.045 | 1.14 | 0.110 | 2.79 | 1.05 | 26.8 | 686 | 17.5 |

| 10 | 12 | 103/30 | 0.045 | 1.14 | 0.110 | 2.79 | 1.09 | 27.6 | 788 | 12.5 |

| 10 | 16 | 103/30 | 0.045 | 1.14 | 0.125 | 3.18 | 1.23 | 31.2 | 1053 | 12.5 |

| 10 | 20 | 103/30 | 0.045 | 1.14 | 0.125 | 3.18 | 1.35 | 34.4 | 1304 | 12.5 |

| 10 | 24 | 103/30 | 0.045 | 1.14 | 0.125 | 3.18 | 1.50 | 38.2 | 1494 | 11.3 |

| 10 | 26 | 103/30 | 0.045 | 1.14 | 0.125 | 3.18 | 1.54 | 39.0 | 1598 | 11.3 |

| 10 | 30 | 103/30 | 0.045 | 1.14 | 0.125 | 3.18 | 1.59 | 40.4 | 1803 | 11.3 |

| 10 | 34 | 103/30 | 0.045 | 1.14 | 0.140 | 3.56 | 1.74 | 44.3 | 2105 | 10 |

| 10 | 36 | 103/30 | 0.045 | 1.14 | 0.140 | 3.56 | 1.74 | 44.3 | 2201 | 10 |

| 10 | 40 | 103/30 | 0.045 | 1.14 | 0.140 | 3.56 | 1.87 | 47.4 | 2464 | 10 |

| 8 | 2 | 67/0.0156 | 0.060 | 1.52 | 0.110 | 2.79 | 0.78 | 19.8 | 367 | 40 |

| 8 | 3 | 67/0.0156 | 0.060 | 1.52 | 0.110 | 2.79 | 0.83 | 21.1 | 452 | 40 |

| 8 | 4 | 67/0.0156 | 0.060 | 1.52 | 0.125 | 3.18 | 0.93 | 23.5 | 577 | 35 |

| 8 | 5 | 67/0.0156 | 0.060 | 1.52 | 0.125 | 3.18 | 1.00 | 25.4 | 683 | 28 |

| 8 | 6 | 67/0.0156 | 0.060 | 1.52 | 0.140 | 3.56 | 1.106 | 28.1 | 804 | 28 |

| 6 | 2 | 184/0.0117 | 0.060 | 1.52 | 0.125 | 3.18 | 0.92 | 23.4 | 525 | 55 |

| 6 | 3 | 184/0.0117 | 0.060 | 1.52 | 0.125 | 3.18 | 0.97 | 24.6 | 641 | 55 |

| 6 | 4 | 184/0.0117 | 0.060 | 1.52 | 0.140 | 3.56 | 1.05 | 26.7 | 785 | 45 |

| 6 | 5 | 184/0.0117 | 0.060 | 1.52 | 0.140 | 3.56 | 1.18 | 30.0 | 983 | 36 |

| 4 | 2 | 165/0.0156 | 0.060 | 1.52 | 0.140 | 3.56 | 1.06 | 26.9 | 728 | 70 |

| 4 | 3 | 165/0.0156 | 0.060 | 1.52 | 0.140 | 3.56 | 1.13 | 28.7 | 913 | 70 |

| 4 | 4 | 165/0.0156 | 0.060 | 1.52 | 0.155 | 3.94 | 1.25 | 31.8 | 1156 | 60 |

| 4 | 5 | 165/0.0156 | 0.060 | 1.52 | 0.155 | 3.94 | 1.31 | 33.2 | 1318 | 48 |

| 2 | 2 | 262/0.0156 | 0.060 | 1.52 | 0.155 | 3.94 | 1.21 | 30.7 | 1000 | 95 |

| 2 | 3 | 262/0.0156 | 0.060 | 1.52 | 0.155 | 3.94 | 1.30 | 33.1 | 1287 | 95 |

| 2 | 4 | 262/0.0156 | 0.060 | 1.52 | 0.170 | 4.32 | 1.45 | 36.8 | 1644 | 80 |

| 2 | 5 | 262/0.0156 | 0.060 | 1.52 | 0.170 | 4.32 | 1.53 | 38.8 | 1900 | 64 |

NOTE 1. Ampacity values shown are for current carrying conductors. A grounding conductor, or one which carries only the

unbalanced current from other conductors, is not counted in determining current carrying capacity

NOTE 2. Correction factor for ambient temperature of 40°C is 0.91