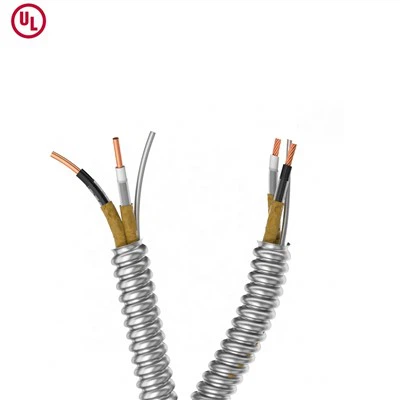

● Conductor: Annealed (Soft) Copper

● Insulation: Polyvinyl Chloride (PVC)

● Jacket: Nylon

● ASTM- All Applicable Standards

● UL Standards 66, 758, and 1063

● National Electrical Code, NFPA 70, 2011 Edition

● TFFN- Dry locations not to exceed 90°C

Application

Available in voltage ratings up to 600 volts, TFFN copper wire is commonly used in lighting fixtures, control panels and appliances, and is ideal for dry locations and situations where flexibility is required, primarily for low-power systems.

Feature

The conductors of TFFN copper wire are made of annealed (soft) copper for excellent conductivity and flexibility. The wires are insulated with polyvinyl chloride (PVC) and further protected with a durable nylon jacket to ensure reliable performance and abrasion resistance.

TFFN wire meets ASTM standards as well as UL Standards 66, 758, and 1063, and complies with the requirements of the National Electrical Code (NEC), NFPA 70, 2011 Edition.

Certification

TFFN copper wire is UL listed, which certifies that TFFN wire is manufactured in accordance with UL Standards 66, 758, and 1063, which cover wire used in lighting fixtures, appliances, and control systems. By choosing UL listed TFFN wire, users can ensure compliance with industry standards and the National Electrical Code (NEC), thereby improving the safety and quality of electrical installations.

Package

Production Line

Greater Wire Manufacturer's state-of-the-art cable factory features an intelligent and digital manufacturing environment. The shift to digital manufacturing not only improves efficiency but also strives to provide customers with the highest reliability products. The smart factory framework ensures a streamlined and error-free production process, minimizes the possibility of human variance, and increases precision that was previously unattainable. The factory strictly adheres to quality control through precise and automated inspection mechanisms. From the beginning to the final stage of the manufacturing process, products are thoroughly inspected. The commitment to quality extends to our inspection accuracy, with automated production equipment achieving an accuracy of 0.002 mm.

customer

Partner

FAQ

Q: What does TFFn wire mean?

A: TFFN wire is thermoplastic flexible fixture nylon wire, similar to THHN wire. It is made of thermoplastic material and features a nylon jacket for added durability and protection. TFFN wire is highly flexible, making it ideal for tight spaces and complex wiring installations. However, it is typically available in a smaller gauge range, making it suitable for use in lighting fixtures, control circuits, and other low-power applications that require flexibility and compactness.

Q: Is TFFN wet rated?

Q: What is the difference between TFFN and MTW wire?

MTW Wire is thermoplastic insulation, often thicker than TFFN for enhanced mechanical durability. Lacks the nylon jacket found in TFFN. Rated for up to 90°C in dry locations and 60°C in wet locations.

Hot Tags: tffn copper wire, China tffn copper wire manufacturers, suppliers, factory, SPT 1 SPT 2 Wire, 300V CSA VW 1 UL1007 Hook Up Wire, multicore flexible cable, multicore rubber cable, HO7V-K, flexible cable

| Conductor | Vinyl Insulation (mils) | Nylon Jacket (mils) | Nominal O.D. (mills) | Approx. Net Wt. Per 1000' (lbs.) | Allowable Ampacities+ | ||

| Size (AWG or kcmil) | No. of strands | TFFN | MTW | ||||

| 18 | 16 | 15 | 4 | 85 | 7 | 6 | 7 |

| 16 | 26 | 15 | 4 | 99 | 11 | 8 | 10 |