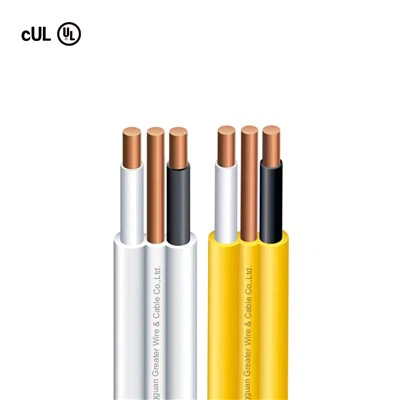

14/3 NMD90 electrical wire has two main types: two-core cable and three-core cable, both with exposed ground conductors. NMD90 cables use annealed (soft) copper conductors and are insulated and protected with heat-resistant thermoplastic polyvinyl chloride (PVC). Protecting the conductors from moisture, chemicals, and physical damage is essential to ensure long-lasting performance and safety. Additionally, each individual conductor is wrapped in a nylon jacket, providing an extra layer of protection. The overall construction includes a durable PVC jacket that encapsulates all conductors, increasing their resistance to external elements and potential wear and tear during installation and use, providing safe, efficient electrical wiring for a variety of applications.

Application

14/3 NMD90 electrical wire offers a variety of applications, making it suitable for both exposed work in dry conditions and concealed work in dry or wet environments. These cables provide flexibility in a variety of installation scenarios. Temperature considerations play a vital role when installing NMD90 cables. Before installation, the cable material must be stored correctly to ensure that it remains above 0°C for at least 24 hours. The maximum allowable conductor temperature for NMD90 cables is 90°C. Able to efficiently handle current while maintaining safety standards, this pre-installation preparation guarantees optimal performance and longevity of the cable in a variety of environmental conditions. The maximum voltage rating is 300 volts.

Certification

NMD90 cable is UL and cUL certified to meet the stringent safety, thermal, and performance standards established by Canada. The cables meet CSA C22.2 No. 48 standards, making them a reliable choice for wiring in residential and commercial buildings in North America.

Package

Factory

Greater Wire is an experienced NMD90 cable manufacturer, located in Dongguan, Guangdong Province, with more than 30+ years of manufacturing experience. The company integrates R&D, production, marketing, and technical support resources to provide a wide range of cable solutions. The company serves major infrastructure projects around the world, including airports, hospitals, manufacturing plants, and educational institutions, and has won wide acclaim for its advanced manufacturing processes, comprehensive testing processes, and strong technical expertise. The company's pursuit of excellence and ability to meet the needs of diverse customers have significantly enhanced its international reputation and market share.

Case

Partner

FAQ

Q: What does NMD90 mean on wire?

Q: What is the voltage of NMD90?

Q: Can you put NMD wire in conduit?

Hot Tags: 14/3 nmd90 electrical wire, China 14/3 nmd90 electrical wire manufacturers, suppliers, factory, rubber cable, tps cable, 110 elastomer cables, single core cable, spt cable, HO7V-U

2 CONDUCTOR

| No. of Conductors |

AWG Size | Insulation Thickness |

Approximate Diameter |

Net Weight | ||||

| Cond. | Bond Wire | in. | mm. | in. | mm. | LB/MFT | KG/KM | |

| 2 | 14 | 14(1) | 0.03 | 0.76 | 0.19x 38 | 4.8x9.7 | 65 | 96 |

| 2 | 12 | 14(1) | 0.03 | 0.76 | 0.21 x41 | 5.3x10.4 | 83 | 123 |

| 2 | 10 | 12(1) | 0.03 | 0.76 | 0.23 x47 | 5.8x11.9 | 120 | 178 |

| 2 | 8 | 10 (1) | 1.14 | 0.045 | 8.4 x17.0 | 0.33 x0.67 | 212 | 315 |

| 2 | 6 | 8 (7) | 1.14 | 0.045 | 9.6 x20.5 | 0.38x0.81 | 335 | 500 |

| 2 | 4 | 8 (7) | 1.14 | 0.045 | 19.500 | 0.770 | 435 | 650 |

| 2 | 3 | 6 (7) | 1.14 | 0.045 | 21.900 | 0.860 | 575 | 860 |

| 2 | 2 | 6 (7) | 1.14 | 0.045 | 23.500 | 0.930 | 675 | 1010 |

3 CONDUCTOR

| No. of Conductors |

AWG Size | Insulation Thickness |

Approximate Diameter |

Net Weight | ||||

| Cond. | Bond Wire | in. | mm. | in. | mm. | LB/MFT | KG/KM | |

| 3 | 14 | 14(1) | 0.03 | 0.760 | 0.340 | 8.700 | 83 | 123 |

| 3 | 12 | 14(1) | 0.03 | 0.760 | 0.360 | 9.100 | 104 | 155 |

| 3 | 10 | 12(1) | 0.03 | 0.760 | 0.400 | 10.200 | 150 | 223 |

| 3 | 8 | 10(1) | 0.035 | 0.890 | 0.610 | 15.500 | 275 | 418 |

| 3 | 6 | 8(7) | 0.045 | 1.140 | 0.900 | 22.800 | 400 | 600 |

| 3 | 3 | 6(7) | 0.045 | 1.140 | 0.920 | 23.400 | 775 | 1150 |

| 3 | 2 | 6(7) | 0.045 | 1.140 | 0.990 | 25.000 | 920 | 1370 |