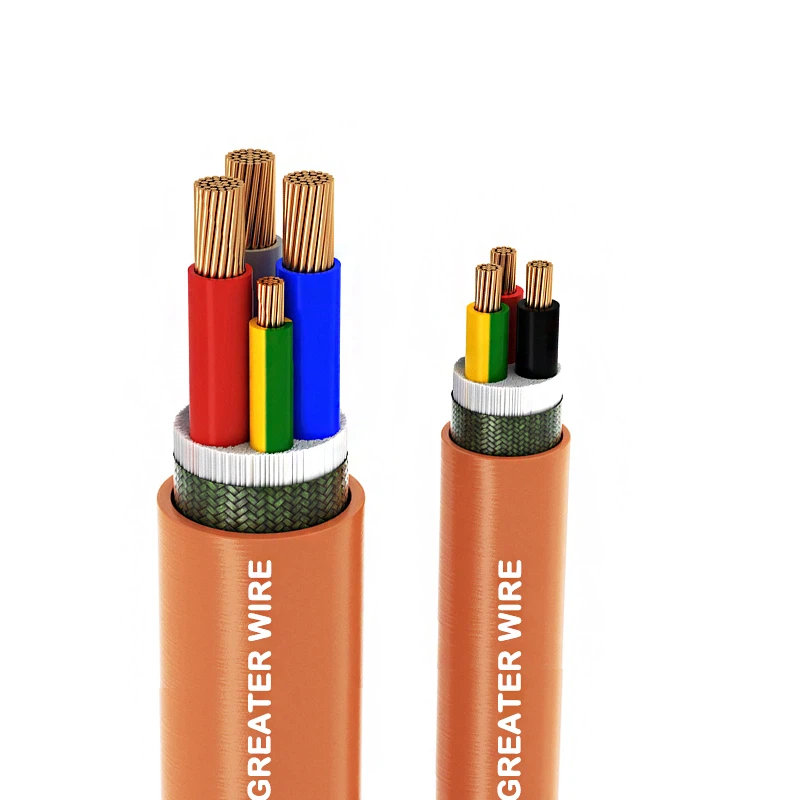

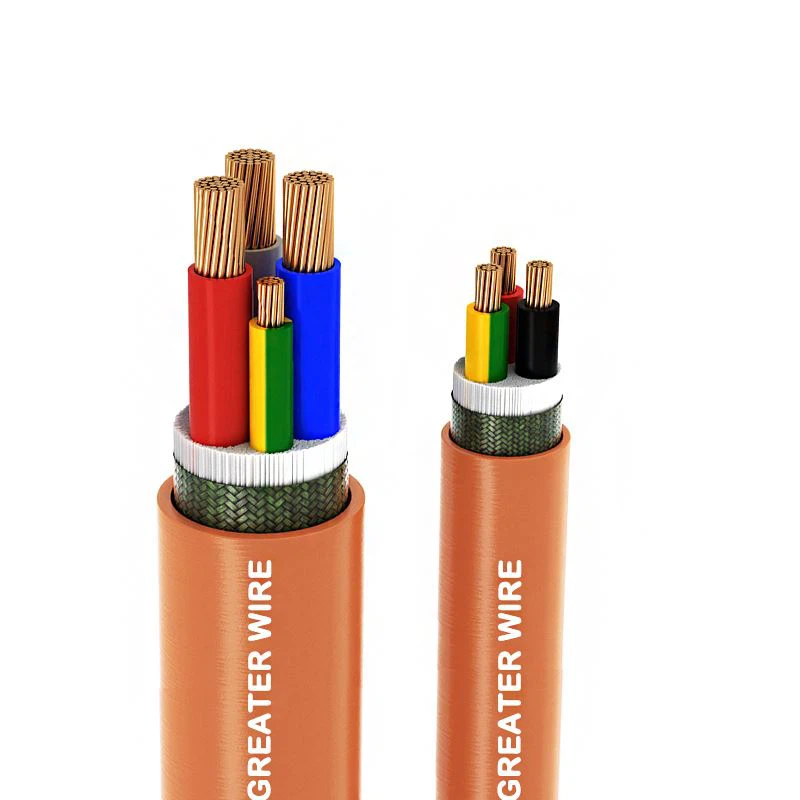

• 3×Conductors: Flexible stranded tinned annealed copper conductor.

• Insulation: EPR.

• Insulation Screen: Semiconductive elastomer.

• Filler: Elastomer centre filler.

• 3×Interstitial Earth Conductor: EPR covered flexible stranded tinned copper conductor.

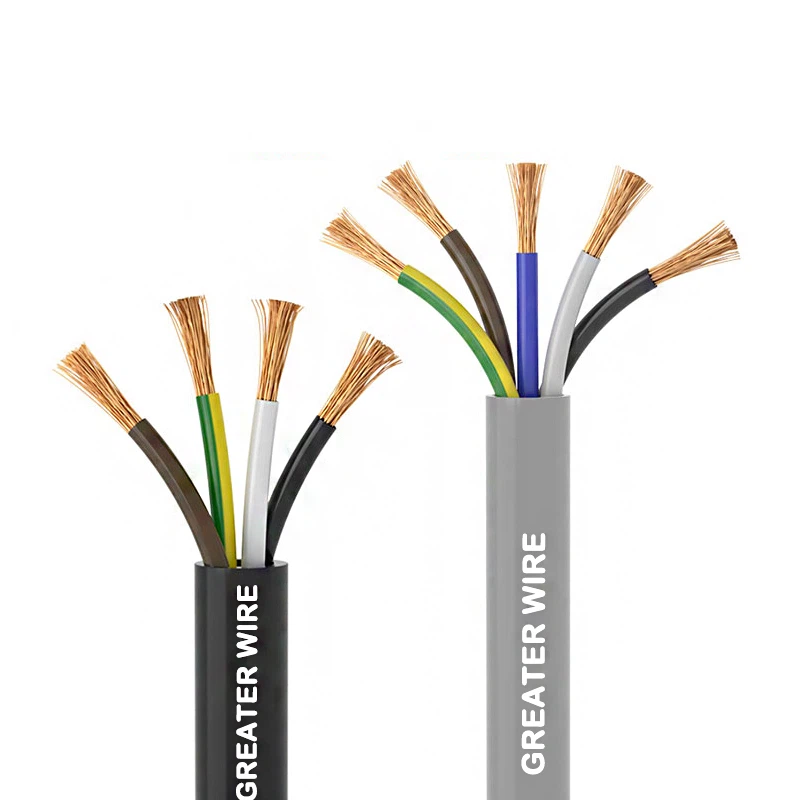

• Inner Sheath: PCP sheath. CPE/CSP sheath can be offered upon request.

• Pliable Armour: Galvanized low carbon (mild) steel strands.

• Outer Sheath: Heavy duty PCP sheath. Heavy-duty CPE/CSP sheath can be offered upon request

Application

Type 412 1.1/1.1kV trailing cable mining is widely used in the power connection of various mobile equipment in open-pit and underground mines, such as mobile mining equipment, electric shovels, drilling rigs, conveyor belt systems, etc. The cable has a rated voltage of 1.1/1.1kV and uses three-core flexible stranded tinned annealed copper conductors, which have good conductivity and corrosion resistance to maintain stable power transmission.

Feature

Type 412 1.1/1.1kV trailing cable mining is a high-strength cable designed for low-voltage mining power supply applications. The insulation material of Type 412 cable is high-performance EPR (ethylene propylene rubber), with a semi-conductive elastomer insulation shielding layer to improve electrical safety and heat resistance. The internal structure of the cable is equipped with an elastic center filler and three EPR insulated grounding conductors to enhance mechanical stability and grounding protection. In order to cope with the frequent dragging and movement in the mining area, Type 412 cable uses flexible steel wire armor (galvanized low-carbon steel stranded wire) to provide excellent tensile and impact protection. The inner and outer sheaths are made of heavy-duty PCP material (CPE/CSP material can also be provided on demand), which has strong wear resistance, oil resistance, chemical corrosion resistance, and flame retardancy, and is suitable for various harsh working conditions.

Certification

Trailing cable mining has passed a number of international and regional authoritative certifications to ensure excellent safety and reliability in harsh mining environments. Our mining cables strictly comply with Australian and New Zealand cable standards such as AS/NZS 2802, AS/NZS 1125, AS/NZS 3808 and AS/NZS 5000.1, and have SAA certification marks, which can be legally used in the Australian and New Zealand markets. These certifications cover many requirements such as conductor structure, insulation performance, mechanical strength, flame retardancy, heat resistance and long-term stability, ensuring that the cables still perform well under harsh working conditions such as high load, humidity, corrosive environment and frequent movement.

Package

Company Introduction

As a professional Australian standard trailing cable mining wire manufacturer, Greater Wire always insists on controlling product quality from the source, selecting high-quality raw materials from around the world, and creating mining cable products with excellent performance and durability. Our factory has long used high-purity oxygen-free copper rods as conductor raw materials, which have stable conductivity and strong antioxidant ability; the conductors are mostly annealed to further improve their service life in humid and corrosive environments. In terms of insulation and sheath materials, Greater Wire uses imported EPR rubber, PCP, CPE, CSP and other high-end elastic materials. These materials not only have excellent heat resistance, oil resistance, flame retardancy, and wear resistance, but also have passed a number of international certifications such as SAA, TUV, UL, CE, etc.

customer

Partner

Hot Tags: type 412 1.1/1.1kv trailing cable mining as/nzs 2802, China type 412 1.1/1.1kv trailing cable mining as/nzs 2802 manufacturers, suppliers, factory

| Nominal Conductor Area | Strand Size | Insulation Thickness | Earth Conductor | Pliable Armour Size | Thickness of Sheath | Nominal Overall Diameter | Nominal Weight | ||

| Strand Size | Thickness of Covering | Inner | Outer | ||||||

| mm² | No/mm | mm | No/mm | mm | No/mm | mm | mm | mm | kg/100m |

| Type 412.1 Class 2 | |||||||||

| 16 | 126/0.40 | 1.6 | 81/0.30 | 0.6 | 7/0.90 | 2.5 | 3.8 | 38.3 | 265 |

| 25 | 209/0.40 | 1.6 | 81/0.30 | 0.6 | 7/0.90 | 2.5 | 3.8 | 38.4 | 294 |

| 35 | 285/0.40 | 1.6 | 81/0.30 | 0.6 | 7/0.90 | 2.5 | 4.0 | 44.6 | 402 |

| 50 | 380/0.40 | 1.7 | 120/0.30 | 0.8 | 7/0.90 | 2.5 | 4.4 | 49.2 | 500 |

| 70 | 203/0.67 | 1.8 | 39/0.67 | 0.8 | 7/0.90 | 2.5 | 4.8 | 55.4 | 655 |

| 95 | 259/0.67 | 2.0 | 48/0.67 | 0.8 | 7/0.90 | 2.5 | 5.4 | 60.1 | 775 |

| 120 | 336/0.67 | 2.1 | 60/0.67 | 1.0 | 7/0.90 | 3.5 | 5.8 | 68.1 | 990 |

| 150 | 427/0.67 | 2.3 | 77/0.67 | 1.0 | 7/0.90 | 3.5 | 6.3 | 73.8 | 1186 |

| 185 | 518/0.67 | 2.5 | 91/0.67 | 1.0 | 7/0.90 | 3.5 | 6.8 | 80.2 | 1360 |

| 240 | 672/0.67 | 2.8 | 119/0.67 | 1.2 | 7/0.90 | 3.5 | 7.5 | 88.7 | 1670 |

| 300 | 854/0.67 | 3.0 | 156/0.67 | 1.2 | 7/1.25 | 4.5 | 8.2 | 100.9 | 2200 |