When it comes to modern electrical wiring, the Twin and Earth Cable is one of the most widely used solutions, especially in residential and commercial installations. This type of cable, often referred to as a TPS cable or TPS electrical cable, consists of two insulated conductors (the live and neutral wires) and an additional uninsulated earth conductor. Its design makes it versatile, easy to install, and safe for many common applications such as lighting circuits, socket wiring, and fixed installations.

Why Do We Need to Join Twin and Earth Cable?

In real-life projects, it is not unusual to encounter situations where a single length of cable isn't enough to reach from the power source to the final outlet or fixture. Renovations, repairs, and extensions often require joining two or more sections of Twin and Earth Cable. For example, imagine a homeowner extending a lighting circuit into a newly built room; rather than rewiring the entire circuit, joining an additional section of TPS cable saves both time and cost. Properly joining cables ensures continuous current flow, consistent safety, and long-term reliability.

Methods of Joining Twin and Earth Cable

Joining electrical cables must always be carried out with precision and with safety as the top priority. With Twin and Earth Cable, there are several commonly used approaches, but the principle is the same: to create a secure and insulated connection that can withstand the required electrical load.

The most widely used method involves employing suitable junction boxes. The stripped ends of the conductors are inserted into terminals and tightened firmly to prevent loosening. Once enclosed in the box, the connection is both electrically reliable and physically protected.

In some cases, connectors or crimp sleeves are used. These require specialized tools but create strong, vibration-resistant joins that are ideal for more demanding environments.

Regardless of the method, it is vital to ensure that each conductor is properly matched-live to live, neutral to neutral, and earth to earth-and that insulation is restored so no bare metal is exposed.

How to Ensure Safety When Joining Twin and Earth Cable

Safety should never be treated as an afterthought. Always isolate the power supply before attempting any connection. Using certified junction boxes and accessories not only guarantees compliance with safety standards but also extends the life of the installation. It's also essential to follow the relevant national standards, such as IEC, AS/NZS, or BS, depending on the project location. For homeowners, it's strongly recommended to hire a licensed electrician, as improper connections can lead to overheating, short circuits, or even fire hazards.

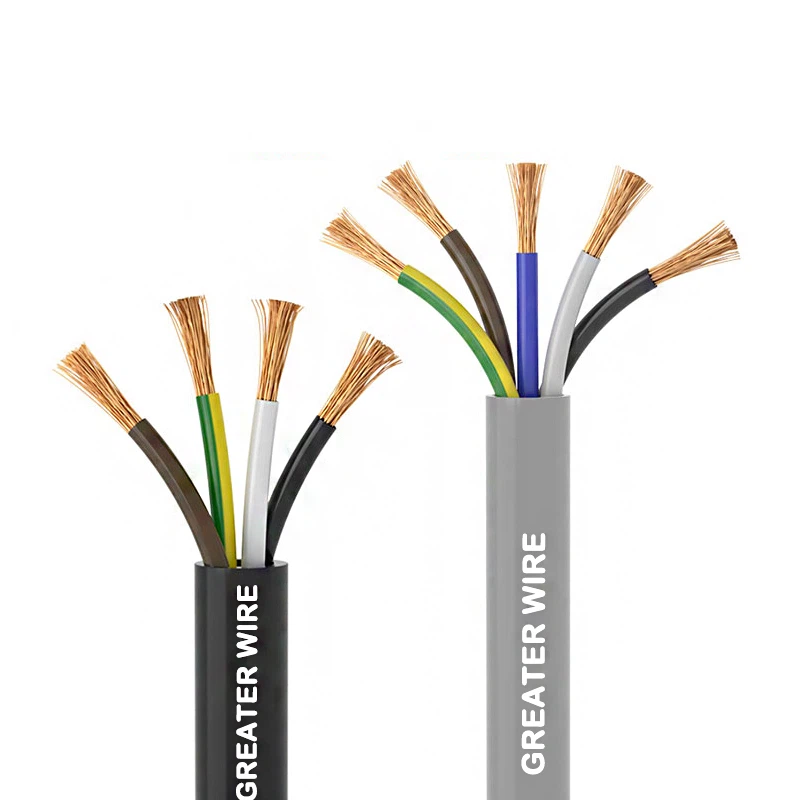

Choosing the Right Twin and Earth Cable for Joining

Not all TPS cables are created equal. The choice of cable size plays a decisive role in ensuring safe and efficient operation. For example, a 1.5mm² Twin and Earth Cable is commonly used for lighting, while a 2.5mm² version is standard for sockets. When cables are joined, maintaining the same cross-sectional area and type ensures consistent performance across the circuit. Using mismatched sizes can create bottlenecks and increase the risk of overheating. Real-world applications highlight this: a kitchen renovation might require extending a 2.5mm² TPS electrical cable to accommodate extra sockets for modern appliances. Choosing the correct cable at the joining stage prevents problems down the line.

How to Purchase TPS Twin and Earth Cable

When purchasing Twin and Earth Cable, it's not enough to look at size alone. Buyers should also consider the certification of the product, the quality of insulation, and whether the cable meets national and international standards. Inferior products may look similar on the outside but can fail prematurely under load. For large-scale projects, it's often necessary to find suppliers who can provide not only standard sizes but also customization in color, length, and even packaging to meet specific market or project requirements. This flexibility allows electricians and contractors to save time on site while ensuring compliance with different regulations.

Why Choose Dongguan Greater Wire & Cable Co., Ltd.

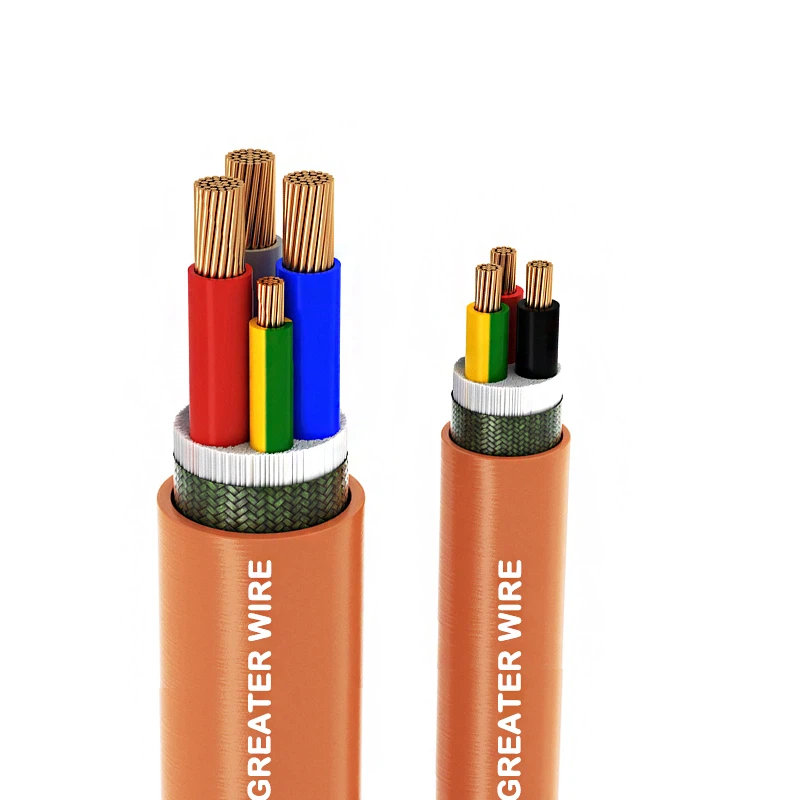

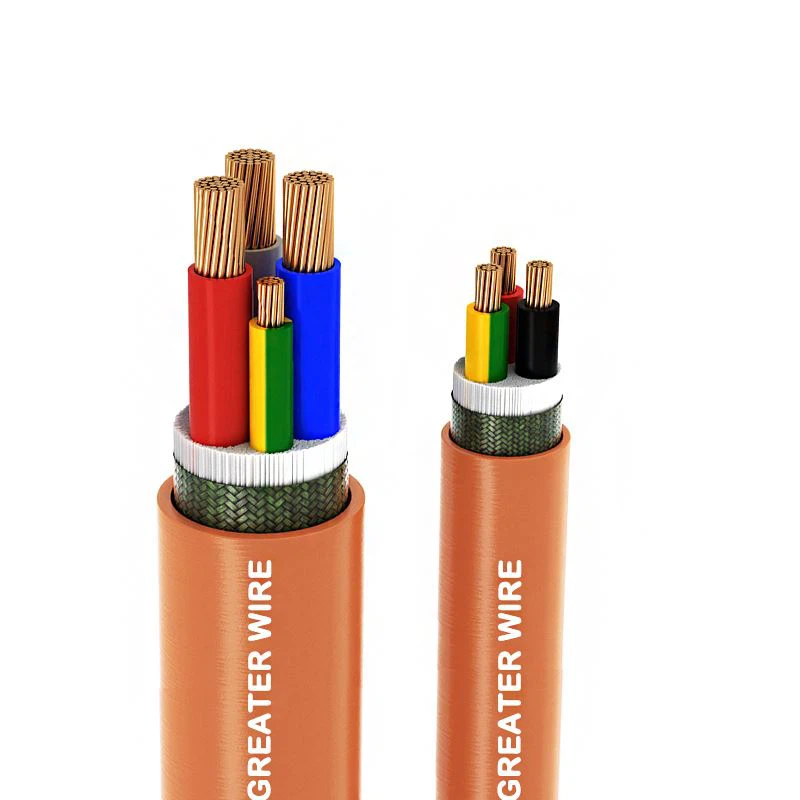

As a leading manufacturer in the cable industry, Dongguan Greater Wire & Cable Co., Ltd. has built a reputation for precision, reliability, and trust. We strictly follow international standards such as IEC, AS/NZS, and BS in every step of our production. Each product undergoes rigorous testing, including voltage resistance, flame retardance, and bending performance, ensuring stable operation in a wide range of installation environments.

What sets us apart is our ability to provide tailored solutions. Beyond common specifications, we offer flexible customization in cable color, length, and packaging to suit diverse markets and projects. Our dedicated customer service team is available 24/7, ready to provide professional cable selection guidance and technical support. With advanced automation, a mature production system, and over 50 international certifications, we guarantee short lead times and stable supply. Our cables are exported to more than 80 countries, including Australia and the Middle East, where we are trusted for our deep knowledge of local standards.

Dongguan Greater Wire & Cable Co., Ltd.

Tel/WhatsApp/Wechat: +86 135 1078 4550 / +86 136 6257 9592

Email: manager01@greaterwire.com