Behind every electronic device, automobile, or piece of industrial equipment lies an invisible foundation: the wiring system. Wires are not simply conduits for electricity-they are the backbone of reliability and safety in every application. When a device overheats, when an engine runs for hours at extreme temperatures, or when cables must be bent and rerouted during installation, the choice of wire material determines whether the system performs reliably or fails prematurely. Many industries once relied heavily on PVC-insulated wires. While PVC is cost-effective and widely available, it has clear limitations in high-temperature, high-flexibility, and long-term performance environments. This is where Silicone Insulated Wire has proven itself to be a game-changer.

What Is Silicone Insulated Wire?

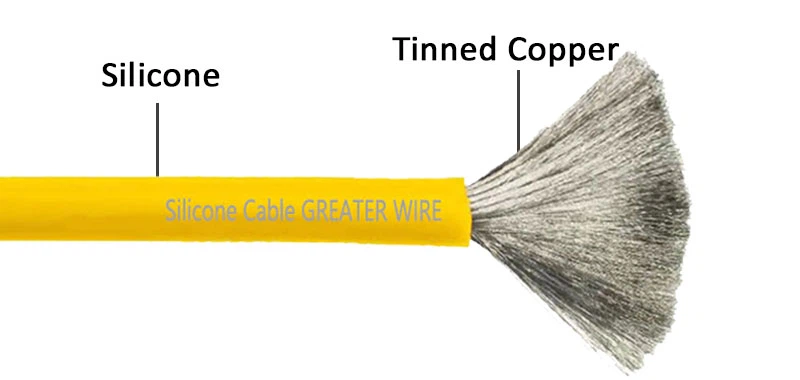

Silicone insulated wire, often referred to as silicone cable, is built with a high-quality conductor-usually stranded bare copper or tinned copper-wrapped in a silicone rubber insulation layer. Unlike traditional thermoplastic insulations, silicone insulation is elastic, highly heat-resistant, and maintains its flexibility across a broad temperature range. This means it can perform reliably at both subzero temperatures and extreme heat, often ranging from -60°C up to +200°C or higher, depending on the specific grade.

Unlike PVC, which can stiffen, crack, or even melt under stress, silicone maintains its properties, making it the preferred option for advanced applications. In short, silicone insulated wire is designed to meet the demands of environments where traditional wiring materials fall short.

The Advantages of Silicone Insulated Wire

The true strength of silicone insulated wire lies in its combination of flexibility and durability. These two qualities translate into a wide range of benefits that make it indispensable in modern industries.

First and foremost, silicone offers exceptional thermal stability. While PVC or other plastics may soften, degrade, or even emit harmful fumes when exposed to high temperatures, silicone insulation remains intact and functional. In automotive engine compartments, for example, where heat is constant and severe, silicone wire ensures steady performance without frequent replacements.

Equally important is flexibility. Silicone insulated wire stays pliable even in extremely low temperatures, which is crucial for applications such as outdoor electronics, aerospace, or vehicles exposed to cold climates. Its ability to bend and twist without cracking or losing insulation integrity makes it easier to install in confined spaces or around tight corners.

Durability extends beyond temperature. Silicone is naturally resistant to chemicals, oils, moisture, and even UV exposure, giving it an advantage in outdoor and industrial environments. Where traditional wiring may corrode, discolor, or deteriorate, silicone wires retain their reliability over long service lives. This durability means fewer replacements, lower maintenance costs, and greater overall safety.

Applications in the Electronics Industry

In the electronics sector, precision and reliability are everything. A failure in wiring can mean a faulty device, consumer dissatisfaction, or even hazardous situations. Silicone insulated wires are increasingly used in appliances such as coffee machines, ovens, and hair dryers, where heat is an everyday factor. In these devices, PVC wiring would quickly degrade, while silicone maintains stable insulation and prevents electrical leakage.

Medical equipment, too, benefits from silicone wiring. Devices such as diagnostic machines or surgical tools demand consistent performance, often under sterilization or exposure to cleaning agents. Silicone's resistance to heat and chemicals ensures long-term safety and reliability.

In industrial electronics, motors, controllers, and sensors often operate in high-stress environments. Here, silicone wire prevents costly downtime by offering the endurance that traditional wiring cannot.

Applications in the Automotive Industry

The automotive industry is perhaps the clearest example of silicone wire's superiority. Inside an engine compartment, wiring is constantly exposed to heat, vibration, oil, and tight installation spaces. Silicone insulated wire withstands these conditions with ease. For conventional vehicles, this means fewer wiring failures and greater overall durability.

For electric and hybrid vehicles, the stakes are even higher. Battery packs, charging systems, and electronic control units generate substantial heat and require wiring that is both heat-resistant and flexible. Silicone insulated wires not only handle these demands but also provide the safety margin necessary for next-generation mobility.

Even in vehicle interiors, where wiring must bend through panels, doors, and dashboards, silicone insulation's flexibility simplifies installation while preventing premature cracking. In short, silicone is not just an upgrade-it is becoming a necessity in modern automotive engineering.

Why Electronics and Automotive Industries Prefer Silicone Insulated Wire

The preference for silicone wiring in these industries comes down to a mix of safety, efficiency, and cost-effectiveness over the long term. While the initial investment in silicone insulated wire may be higher than PVC alternatives, its durability and long service life more than compensate for the cost. The fewer replacements required, the less downtime experienced, and the safer the overall system, the more value silicone provides.

In electronics, safety and brand reputation are paramount. Using silicone wire means fewer recalls, fewer warranty claims, and happier customers. In automotive applications, it directly contributes to vehicle reliability and consumer trust. Whether it's ensuring that a family's oven remains safe or that an electric car's battery system operates smoothly, silicone insulated wire consistently proves its worth.

How to Choose Silicone Insulated Wire

Choosing the right silicone wire depends on understanding your project requirements. For electronics, voltage levels, wire gauge, and insulation thickness are critical. For automotive use, heat resistance, flexibility, and chemical resistance should guide the selection. Always consider certifications such as UL, IEC, or AS/NZS standards, which guarantee compliance and safety.

It is also wise to consult a professional manufacturer who can provide guidance on customization. Factors like conductor material (bare copper vs. tinned copper), insulation thickness, and even color coding can be tailored to fit specific projects. This ensures not only technical compliance but also installation efficiency.

Why Choose Dongguan Greater Wire & Cable Co., Ltd.?

At Dongguan Greater Wire & Cable Co., Ltd., we understand the importance of wiring solutions that perform reliably in the most demanding environments. With over 30 years of deep industry experience, we have developed expertise in producing high-performance cables that meet the evolving needs of electronics and automotive manufacturers worldwide.

Our 50,000+ square meter modern factory is equipped with advanced automated production lines, ensuring consistent quality and efficiency. We hold 50+ international certifications, including IEC, AS/NZS, and BS standards, demonstrating our commitment to compliance and global excellence.

What sets us apart is not just our scale, but our flexibility. We provide customizable solutions, from conductor size to insulation color, from packaging options to specialized performance requirements. Whether you need silicone insulated wire for high-end electronics, automotive wiring harnesses, or specialized industrial applications, we can deliver a solution tailored to your exact specifications.

With robust export experience, we serve clients across the UK, Europe, Australia, Southeast Asia, and beyond. Our dedicated 24/7 customer service ensures that your questions are answered, your projects supported, and your timelines met.

In the competitive world of electronics and automotive industries, success depends on reliability, safety, and performance. Silicone insulated wire provides all three. Its combination of heat resistance, flexibility, durability, and long service life makes it the clear choice for manufacturers who want to deliver the best. While other materials may suffice in less demanding applications, when safety and longevity matter, silicone insulated wire is unmatched.

Choosing silicone insulated wire is not simply about buying a cable-it's about investing in the long-term success of your product and your brand. Partner with a trusted manufacturer, and you gain not only a superior product but also the confidence that your systems will perform flawlessly for years to come.

Dongguan Greater Wire & Cable Co., Ltd.

Tel/WhatsApp/Wechat: +86 135 1078 4550 / +86 136 6257 9592

Email: manager01@greaterwire.com