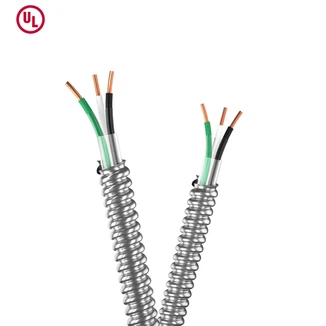

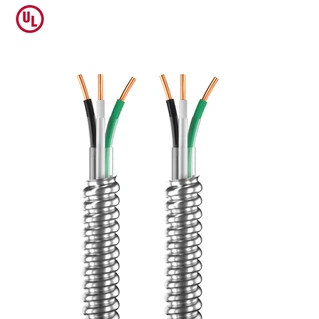

MC cable(Metal Cladd cable) is a type of cable widely used in power transmission, known for its sturdy metal sheath structure. MC cables play an important role in various environments, including residential, commercial, and industrial applications, due to their excellent mechanical protection capabilities and durability. Different specifications of MC cables, such as 6 3 MC wire, 10 2 MC wire, 6 3 armored cable, 10 3 armored cable, 12 2 metal clad wire outdoor MC cable,12 2 stranded MC cable,12 3 armored cable, Suitable for different electrical installation scenarios. This article will explore in detail the applicable environment of MC cables to help electrical engineers and construction personnel make the right choices.

1. Indoor installation environment

1.1 Commercial and residential buildings

MC cables are widely used in power supply systems in commercial and residential buildings, especially in situations where enhanced protection capabilities are required. For example, 6 3 MC wire is suitable for supplying power to high-power devices such as electric stoves, water heaters, and central air conditioning. 10 2 MC wire is commonly used for medium power appliances such as ovens and washing machines.

The metal sheath of MC cables enables them to resist mechanical damage without the need for additional conduit protection, which is particularly advantageous in narrow spaces and complex wiring environments. In addition, MC cables also comply with NEC (National Electrical Code) requirements and can be used in dry and humid environments, suitable for installation in walls, ceilings, and underground piping systems.

1.2 High rise buildings and industrial plants

In high-rise buildings and industrial plants, 10 3 armored cables and 12 3 armored cables provide additional wires, making them suitable for power systems that require multi wire connections. The motors, control panels, and lighting systems in industrial plants often require the use of these MC cables to ensure the stability and safety of power supply.

2. Outdoor and harsh environmental applications

2.1 Outdoor and humid environments

The outdoor MC cable is designed specifically for outdoor applications, and its metal sheath not only provides mechanical protection, but also has good waterproof performance, making it suitable for outdoor environments such as outdoor lighting, electric doors, and landscape lighting systems. For underground wiring, the sturdy structure of MC cables enables them to effectively prevent soil pressure and moisture erosion without the use of conduits.

2.2 Industrial environment and adverse weather conditions

In industrial environments, MC cables are commonly used in places with high temperature, high humidity, and chemical corrosion. For example, the 6 3 armored cable has a larger wire size and is suitable for high-power loads such as industrial equipment and high-voltage motors. In addition, chemical plants, power plants, and manufacturing workshops often use MC cables to ensure the stability and durability of the power system.

In extreme weather conditions, such as rainstorm, severe cold and high temperature, the metal sheath of MC cable can provide additional protection to ensure that the cable will not fail due to changes in the external environment. For example, the 12 2 stranded MC cable uses multiple conductors to improve flexibility and is suitable for applications that require frequent bending, such as outdoor lighting systems and temporary power wiring.

3. Application of underground wiring

MC cables are also suitable for underground wiring, such as parking lot power supply systems, municipal engineering, and subway facilities. Its metal sheath can effectively prevent soil pressure and corrosion. Especially the 12 2 metal clad wire, due to its smaller diameter, is suitable for wiring in underground lighting and communication systems. The 6 3 armed cable is commonly used in underground main power lines to provide stable power supply for high load equipment.

4. Application of mechanical equipment and control systems

In mechanical equipment and automation control systems, MC cables are widely used for motor control, sensor power supply, and data transmission due to their excellent seismic resistance and durability. For example, the 12 2 stranded MC cable, due to its multi conductor structure, is suitable for cable routing that requires high flexibility, such as mobile robotic arms, elevator systems, and robotic automation equipment. In addition, the 10 3 armored cable can be used for supplying power to electric motors, ensuring reliable operation of high-power equipment.

5. Construction site and temporary power application

At the construction site, MC cables can be used for temporary power supply, such as mobile lighting systems, construction machinery, and emergency power equipment. Its metal sheath can effectively prevent cable damage caused by impact, pulling, or trampling during construction, improving safety. For example, the 12 3 armored cable is suitable for temporary distribution boxes, providing power distribution for multiple circuits to ensure stable operation of the electrical system on the construction site.

MC cables, with their sturdy metal sheath design, can perform excellently in various environments. From residential and commercial buildings to industrial plants, as well as outdoor wiring and underground installations, MC cables can provide reliable power transmission. Different specifications of MC cables, such as 6 3 MC wire, 10 2 MC wire, 6 3 armored cable, 10 3 armored cable, 12 2 metal clad wire outdoor MC cable,12 2 stranded MC cable,12 3 armored cable, Suitable for different application scenarios, ensuring the safety and durability of electrical systems. Therefore, when selecting MC cables, the most suitable model should be chosen based on the specific application environment, load requirements, and installation requirements to ensure the long-term stable operation of the power system.