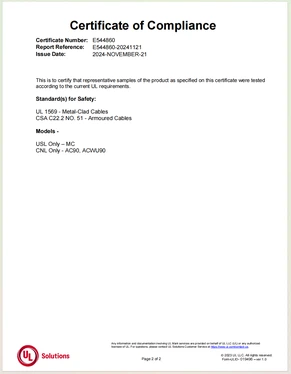

Metal clad cable are a type of cable widely used in the field of electrical engineering, favored by many electricians and engineers due to their sturdy and durable structure. However, many people have a question when choosing MC cables: can MC cables be used outdoors?

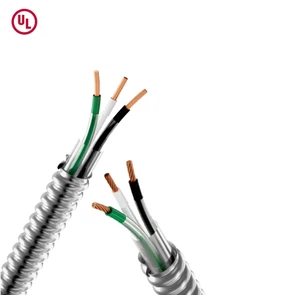

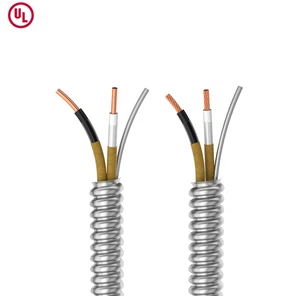

Basic structure of MC cable

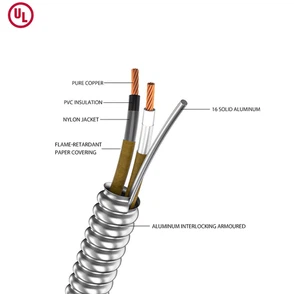

MC cable consists of conductor, insulation layer, metal sheath, and outer sheath (if any). Metal sheaths are usually made of aluminum alloy or galvanized steel to provide some mechanical protection and also have a certain shielding function. This type of cable includes various specifications, such as 8 3 armored cable, 12 2 mc cable 250, 4 4 mc cable, 4 mc cable, 10 mc cable, 10 3 mc wire, etc.

Some MC cables have additional protective layers, such as jacketed MC cables or PVC coated MC cables 12 2, which help improve the weather resistance of the cables and make them more suitable for outdoor environments.

Applicability of MC cables outdoors

MC cables are essentially designed for indoor environments, such as commercial buildings, industrial facilities, and residential wiring. However, under certain conditions, MC cables can be used for outdoor applications, depending on the type of cable and environmental requirements.

1. Is it exposed to outdoor environments?

If MC cables are directly exposed to outdoor environments such as sunlight, rain, and extreme temperatures, their metal sheaths may lose their protective function due to corrosion or oxidation. For exposed MC cables, it is recommended to use black MC cables or PVC MC cables. These cables with PVC outer sheaths can provide additional waterproof and UV protection.

2. Is it buried underground?

If MC cables are to be buried underground, it is necessary to ensure that the cables comply with the relevant requirements of NEC (National Electrical Code). Generally speaking, exposed MC cables are not suitable for direct burial, but if they are jacketed MC cables or PVC coated MC cables 12 2, these cables with additional protective layers can better resist moisture and corrosive substances in the soil.

3. Is it used in humid or corrosive environments?

For environments with high humidity or strong corrosiveness, such as coastal areas or chemical plants, ordinary MC cables may not provide sufficient protection. At this point, it is recommended to choose PVC coated MC cable 12 2 or other MC cables with PVC outer sheath to ensure long-term reliability.

4. Does it comply with local electrical regulations?

In certain regions, NEC or local electrical regulations may have specific requirements for the use of outdoor MC cables, such as the mandatory use of waterproof connectors or additional protective tubes. Therefore, before installation, it is necessary to carefully review relevant standards to ensure compliance with all safety regulations.

What outdoor scenarios are MC cables suitable for?

Although MC cables are typically used indoors, they are still a viable option in certain specific outdoor scenarios:

Outdoor equipment power supply for industrial facilities, such as outdoor motors, power boxes, or lighting equipment in factories, can be provided with reliable power supply using sturdy and durable cables such as 8 3 armed cables or 4 4 mc cables.

External wiring of buildings: When cables need to pass through the exterior walls of buildings or connect outdoor equipment, jacketed MC cables or PVC MC cables with sheaths may be ideal choices.

Bridge and tunnel engineering: In some special projects, MC cables may be used for power supply to bridges or tunnels, provided they have sufficient corrosion resistance and mechanical protection capabilities.

How to improve the outdoor durability of MC cables?

If MC cables must be used outdoors, the following points can effectively improve their durability:

1.Choose MC cables with outer sheaths, such as PVC coated MC cable 12 2, which can provide better waterproof and UV protection.

2.Use waterproof joints and sealing devices to prevent moisture from entering cable connection points and reduce the risk of corrosion.

3.Avoid direct exposure to extreme environments: If possible, use cable conduits or coverings to protect MC cables from wind and rain.

4.Regular inspection and maintenance: After long-term use, check whether the cable is corroded or damaged for timely replacement.

MC cables can be used outdoors under certain conditions, but appropriate protective measures must be taken to ensure their durability and safety. If the MC cable is directly exposed outdoors, priority should be given to models with additional protective layers such as black MC cable, jacketed MC cable, or PVC coated MC cable 12 2. In addition, local electrical regulations should be consulted before installation to ensure compliance with all safety requirements. Through reasonable selection and installation, MC cables can provide reliable power transmission in appropriate outdoor application scenarios.