In photovoltaic (PV) power generation systems, solar cables and solar conductors are vital components responsible for safely and efficiently transmitting the current generated by solar panels to inverters and other equipment. Voltage level is a key factor in

design and selection, which is directly related to the safety, efficiency and long-term stability of the system. Understanding the voltage level of solar cables is essential for correctly selecting the appropriate cables and ensuring the safe operation of photovoltaic systems.

This article will explore the voltage levels of solar cables and solar conductors in detail, explain their role in photovoltaic systems, and discuss the selection and impact of voltage levels.

1. Voltage Level of Solar Cables

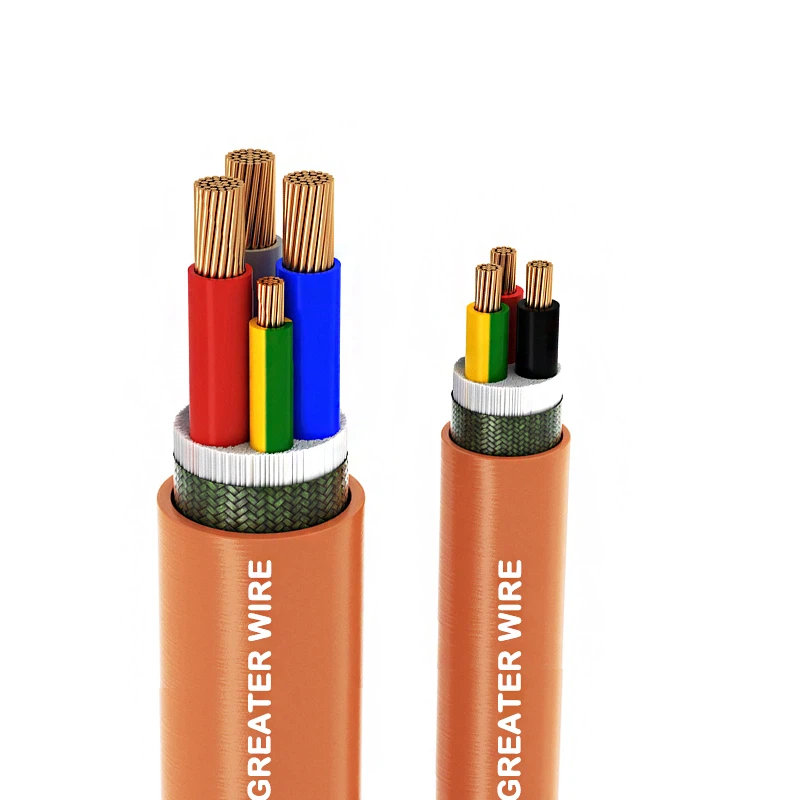

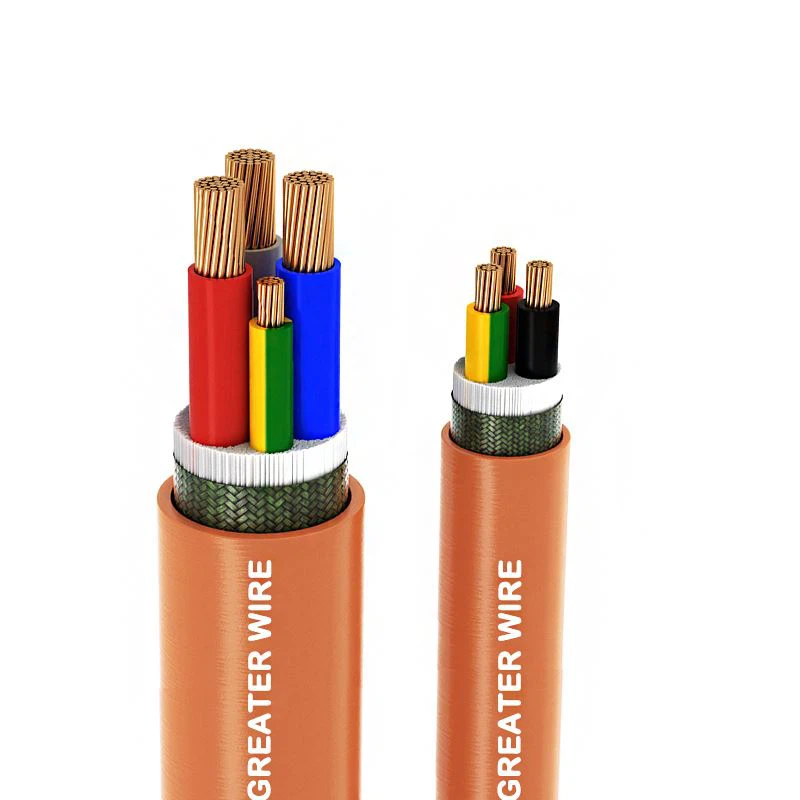

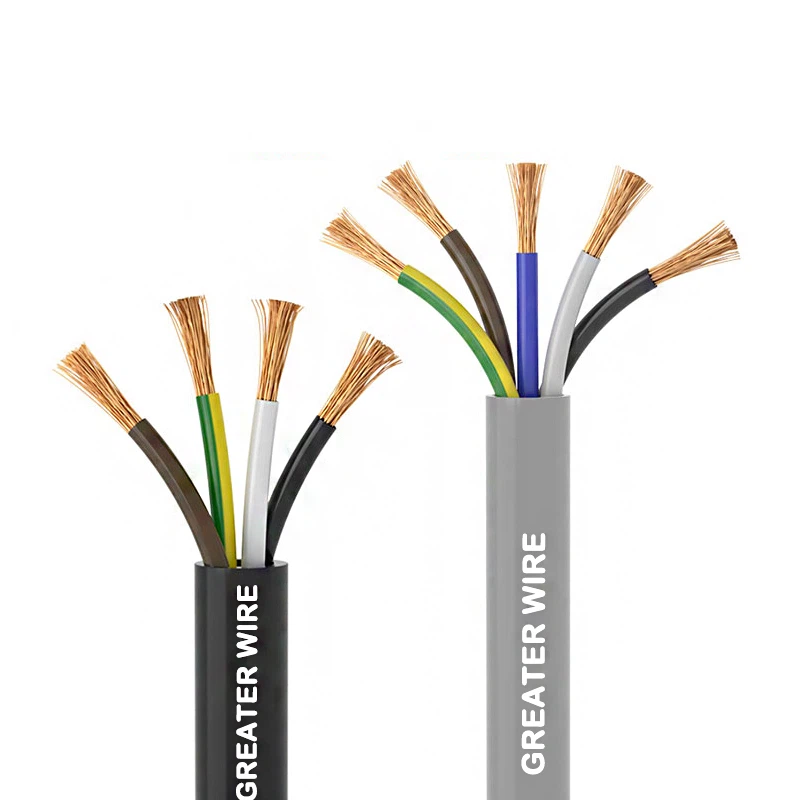

Solar cables are cables designed specifically for photovoltaic power generation systems, with good weather resistance, high temperature resistance and UV resistance. According to different working environments and photovoltaic system requirements, the voltage levels of solar cables are generally divided into low voltage and medium voltage cables. Understanding these voltage levels is essential for selecting the appropriate cables.

1. Low Voltage Cable (LV)

Low voltage cables are usually used for direct current (DC) circuits in solar systems, and their operating voltage generally does not exceed 1000V. Most residential and commercial solar power generation systems use low voltage cables. The typical rated voltage of low voltage solar cables is 600/1000V, which means that the cables can operate safely at 600V and can withstand an overload voltage of 1000V for a short period of time.

Common applications:

Residential photovoltaic systems

Small commercial photovoltaic systems

DC circuits connected to inverters

Low voltage cables are the most common type of solar cables and can meet the needs of most solar systems. They are suitable for most solar panels and inverter systems, can withstand high temperatures and UV radiation, and have good resistance to moisture and corrosion.

2. Medium Voltage Cable (MV)

Medium voltage cables are mainly used in large photovoltaic power generation systems or photovoltaic power plants to transmit power from multiple photovoltaic arrays to inverters or distribution systems. The rated voltage of medium voltage cables is usually between 3kV and 36kV, and in some special applications, the voltage level can be higher.

Common applications:

Internal power transmission in photovoltaic power plants

Large commercial or industrial photovoltaic systems

Power transmission between photovoltaic power generation systems and the grid

Medium voltage cables can provide higher power transmission capabilities and are suitable for large-scale photovoltaic power generation projects. These cables not only have higher voltage carrying capacity, but also need to have stronger insulation and arc resistance.

3. High Voltage Cable (HV)

High voltage cables are generally used for long-distance power transmission between ultra-large photovoltaic power generation systems and power networks. Because high voltage cables need to withstand higher currents and voltages, their insulation materials and design requirements are more stringent. Typical high voltage cables are rated at more than 36kV and are used to transmit power generated by power plants to the power grid.

Common applications:

Connection between photovoltaic power generation systems and the main power grid

Long-distance power transmission of ultra-large photovoltaic power stations

The use of high-voltage cables is more complicated and is mainly used in scenarios that require large-scale power transmission.

2. Voltage requirements for solar cables and solar conductors

Solar cables and solar conductors are important media for power transmission. The voltage level of their design not only determines the maximum voltage they can withstand, but is also closely related to their insulation performance, conductivity and overall reliability.

1. Voltage level of solar cables

The voltage level of solar cables refers to the operating voltage range that the cable can withstand. Most solar cables in photovoltaic systems use low-voltage cables (600/1000V), which can effectively transmit current and withstand voltage fluctuations in daily work. Especially in residential and commercial installations, low-voltage cables meet most of the power needs.

For example:

A solar cable that meets the IEC 60216 standard is usually marked with a rated voltage of 0.6/1kV, indicating that the cable is suitable for voltage environments between 600V and 1000V.

The insulation material of solar cables is usually XLPE (cross-linked polyethylene) or PVC (polyvinyl chloride), which has excellent electrical insulation properties and high temperature resistance.

2. Voltage requirements for solar conductors

Solar conductors are part of the solar cable, and their voltage requirements are usually the same as those of the cable. When selecting solar conductors, in addition to the voltage level, the cross-sectional area, conductivity and environmental resistance of the conductors need to be considered. Solar conductors are usually used for series and parallel connections of photovoltaic panels, so their voltage level must match the voltage of the entire photovoltaic system.

3. Selection of rated voltage

When choosing the appropriate voltage level, the following factors should be considered:

Rated voltage of photovoltaic panels: Photovoltaic panels usually operate in a lower voltage range, especially in low-voltage photovoltaic systems. Therefore, the selected cable voltage level should not exceed the rated voltage of the panel.

Inverter voltage range: The rated voltage of the inverter must match the voltage output by the panel to ensure that the photovoltaic system can work stably and efficiently.

Working environment and climatic conditions: Solar cables are exposed to outdoor environments all year round and need to resist harsh conditions such as ultraviolet rays, moisture, and temperature changes. Therefore, the insulation level of the cable should adapt to these environmental challenges.

3. Insulation materials and voltage levels of solar cables and conductors

Insulation materials are key factors in determining the voltage level and safety performance of solar cables. The insulation material of solar cables must not only have sufficient electrical insulation performance, but also have the characteristics of high temperature resistance, ultraviolet resistance, and weather resistance to adapt to various external environments that may be encountered in solar systems.

Cross-linked polyethylene (XLPE)

Cross-linked polyethylene is currently the most common insulation material for solar cables. It has excellent resistance to high temperatures, voltage breakdown and UV rays, and can operate over a wide temperature range, adapting to the environment where photovoltaic panels and cables are exposed to sunlight for a long time.

Polyvinyl chloride (PVC)

Polyvinyl chloride is another common insulating material. Although its high temperature resistance is not as good as cross-linked polyethylene, it still has sufficient insulation performance in most low-voltage photovoltaic systems. PVC cables are generally more economical and suitable for residential or small commercial photovoltaic systems.

Rubber materials

In some special applications, such as where flexible cables are required, rubber materials may be used as insulation materials for solar cables. Rubber cables have excellent mechanical properties and tear resistance, and are suitable for installation environments that require flexible bending.