1. Overview of the THHN Wire Color Coding System

In electrical engineering, THHN wires are often color-coded to distinguish the functions of different circuits (such as phase, neutral, ground, and control wires). Common systems are based on standards such as NFPA 70 (NEC, the US National Electrical Code), NEMA (the US National Electrical Manufacturers Association), and GB50303/GB-5023 in China. While color definitions vary slightly between standards, the following principles generally apply:

1. Phase (Phase/Live): Use black, red, blue, and other colors. In multi-phase systems, phases are identified sequentially.

2. Neutral: Use white or gray.

3. Ground (Ground/Equipment Ground): Use green or green-and-yellow.

4. Other Uses: Yellow, orange, and brown are sometimes used for control wires or backup phases.

Color selection should comply with electrical safety regulations to ensure accurate identification and avoid potential safety hazards caused by misconnections.

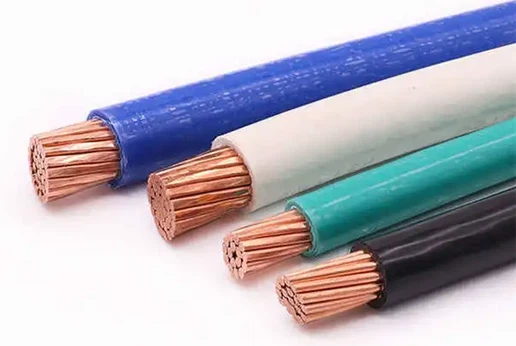

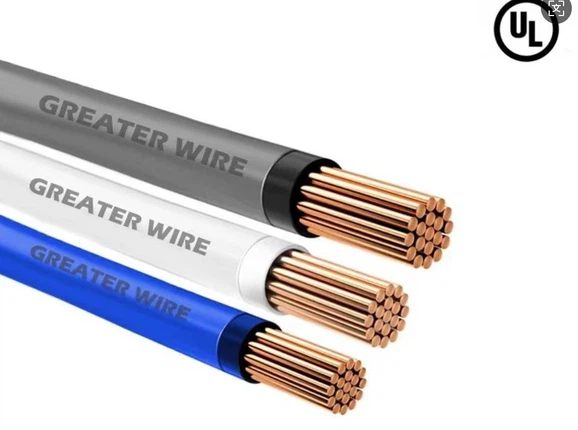

2. THHN wire Common Colors and Their Specific Meanings

The following details several common colors found in THHN wiring, their meanings, and uses.

2.1 THHN cable Black - Main Phase

Commonly used for the "hot" wire in single-phase systems or Phase 1 (L1) in three-phase systems.

Simple and practical wiring: Most commonly used in single-phase 120V/240V wiring.

Features: Black wires without additional markings are assumed to be live phases, requiring particular caution during construction and maintenance.

2.2 THHN cable Red - Phase/Phase 2

Commonly used for Phase 2 (L2) in three-phase power systems.

In single-phase systems, it is also used for switching control lines or branching load phases.

Red is easily distinguishable and aids identification in conduit or cable trays where multiple phases share common wiring.

2.3 THHN cable Blue - Third or Neutral Phase/Control Wire

In three-phase systems, it is usually used for Phase 3 (L3).

In some control systems, blue can also be used as a "neutral control wire" or "backup function wire."

Using blue prevents confusion with black or red, improving safety.

2.4 THHN cable White - Neutral

In AC power supplies, the neutral wire is typically grounded and serves as the negative return line.

White conductors are generally designated as neutral conductors in domestic and international standards, but it is important to ensure that the white conductor is pure and undyed. Sometimes, an additional "N" mark is required on white conductors.

When using white, do not cross it with a phase conductor.

2.5 THHN cable Green/Green-Yellow - Protective Earth (PE)

Green or green with a yellow stripe is used for equipment protective earth (PE), contacting the metal casing or ground grid.

The NEC explicitly states that green/green-yellow can only be used as grounding conductors and not for neutral.

Green-yellow is particularly visually more striking and is the most widely recommended grounding color today.

2.6 THHN cable Gray - Neutral (Alternative)

In some systems, gray is also used as the neutral conductor, replacing white.

This design facilitates identification when multiple neutral conductors are present and avoids confusion when white conductors are colored.

2.7 Other Colors: Yellow, Orange, Brown, etc. - Spare Phase/Control Wires

Yellow: Commonly used for spare phases (such as L4 in four-phase systems) or auxiliary power phases.

Orange: Sometimes used as a hazard warning wire or as an intermediate control wire in industrial control circuits.

Brown: In some IEC/European standards, brown is used for L1/L phase; blue for neutral; and green and yellow for ground.

While the common THHN colors are black/red/blue/white/green, these additional colors are also used when further refinement is required.

3. Color Differences and Precautions in Different Regions or Standards

While the above Thhn wire's color rules are widely adopted in many countries, local standards still vary slightly and should be strictly followed according to the specific local regulations of the project:

| Region/Standard | Phase Color | Neutral | Ground | Other Notes |

| US NEC/NEMA | Black, red, and blue (three-phase) | white or gray | green or green/yellow | yellow, orange, and brown are used for control and standby functions. |

| China GB Standard | Black, red, and blue (three-phase) | Light blue or gray (sometimes white) | Green/yellow | Control lines are sometimes distinguished by other colors |

| European IEC Standard | Brown, black, and gray (three-phase) | Blue | Green/yellow | Compared to American color schemes, careful mixing is recommended. |

| Japanese JIS Standards | Black, red, and white (three-phase) | Cyan (gray-blue); older systems may use white | Green, green-yellow | Some older equipment still uses white as the neutral wire; please be aware of standard changes. |

If the project involves imported equipment or overseas wiring, special attention should be paid to differences in color schemes. For example, if European equipment is introduced to a Chinese site and brown is mixed with local installations as L1 wiring, it could lead to misidentification. Therefore, if necessary, label the connections or use double marking to ensure safety and clarity.

4. Safety Specifications and Selection Recommendations

4.1 Safety Specifications

1.Select colors strictly in accordance with the electrical specifications of the project location: Avoid mixing multiple systems that could lead to misidentification.

2.Avoid color coverage or damage: If white wires are covered with paint or stains, they lose their identification function; repairs should be made promptly.

3.Do not use the ground wire as the neutral wire: Even if the green wire is connected to the ground and used as the neutral, it poses a significant safety risk.

4.Avoid using colors for meaningless decorative distinctions: The color of each wire should have a functional distinction.

5.Labels and Markings: In multi-color or double-wire systems, heat shrink tubing, wire number tape, or colored labels can be used for further identification.

6.Compliance Acceptance Marking: After completion, electrical safety testing should be conducted to confirm that there are no risks of misconnections, leakage, or short circuits.

6.2 Selection Recommendations

1.For conventional residential/commercial wiring: Black (L1), red (L2), blue (L3), white for neutral, and green and yellow for grounding meet standard requirements.

2.Industrial electromechanical wiring: Yellow and orange can be added as auxiliary or control lines to match the control cabinet device wiring diagram.

3.Specific function lines, such as signal lines and emergency disconnect lines, can use colors different from standard phase lines but with unified regional identification.

4.Spare or upgrade preparation: Reserve yellow or orange spare lines in main conduit or cable trays to facilitate future expansion.

5.Cross-standard equipment integration: When importing equipment to a site, additional color information can be provided on external conductor connectors.

6.Cable specification matching: In addition to color, THHN cable specifications also need to consider rated voltage, conductor size (AWG/mm²), thermal rating, and oil and moisture resistance.

5. Practical Scenario Examples and Summary

5.1 Practical Example

Residential Single-Phase System:

Black: Phase (L, Hot)

White/Gray: Neutral (N)

Green and Yellow: Ground (PE)

Three-Phase Load Distribution:

Black: L1

Red: L2

Blue: L3

White/Gray: Neutral (N)

Green and Yellow: Ground (PE)

Inside the Control Cabinet:

Black/Red/Blue: Three-Phase Power Input Cables

White/Gray: Neutral or Control Neutral Cable

Green/Green and Yellow: Ground

Yellow: Redundant Backup Cable or Control Output Cable

Orange: Signal Feedback Cable or Danger Indicator Cable

Each cable color corresponds to a specific function, which aids in construction, maintenance, and troubleshooting.

5.2 Summary

THHN cables are widely used in building and industrial power distribution due to their high-temperature resistance, excellent mechanical protection, and strong chemical resistance. Color coding is crucial for safety identification, electrical construction, student learning, and even project acceptance. Common colors-such as black (phase), red/blue (multiphase), white/gray (neutral), and green/green-yellow (ground)-form the basic identification system. Yellow, orange, and brown are often used for auxiliary, control, or extended functions.

In actual operation, you should:

1.Strictly adhere to local or project standards.

2.Ensure that wire colors are clear, correctly labeled, and free of smearing errors.

3.Use appropriate colors for corresponding purposes, and reserve extension colors.

4.If there is a conflict between different regional standards, additional markings or secondary differentiation are essential.

Ensuring the safety and maintainability of THHN wiring through standardized selection and installation is a key guarantee of electrical project quality.