1, TPS cable definition

tps electrical cable stands for "Thermoplastic heated cable". This is a flat cable widely used in electrical wiring systems, consisting of copper conductors inside and wrapped with thermoplastic insulation and sheath layers on the outer layer. tps electrical cable typically have two or three core designs and are suitable for scenarios where AC voltage generally does not exceed 600V.

electrical tps cable are widely regulated and used in Australian and New Zealand standards (AS/NZS 5000 series) due to their simple structure, flexible installation, and good safety performance, making them one of the main low-voltage cables in the construction industry in these countries. In the industry, it is often referred to as a "Flat Twin and Earth" cable or simply a "Flat TPS Cable".

2, The structural composition of electrical tps cable

The core of TPS cable lies in its simple and practical structure, mainly composed of the following parts:

1. Conductor

The conductor part is usually made of twisted or solid oxygen free copper material, which has good conductivity. Copper wire can be single stranded (used for fixed wiring) or multi stranded (used for flexible wiring), and its cross-sectional area varies depending on the current carrying capacity. Common specifications include TPS cable 1.0mm ², TPS cable 1.5mm ², TPS cable 2.5mm ², TPS cable 4mm ², etc.

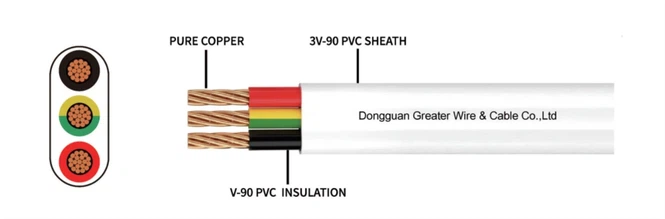

2. Insulation layer

Each copper conductor is coated with a layer of thermoplastic insulation material, typically V-90 polyvinyl chloride (PVC). This material has good electrical insulation performance and heat resistance and flame retardant properties.

3. Earth Wire

Most TPS cable are equipped with an uninsulated or green/yellow insulated grounding conductor for equipment or circuit grounding protection, enhancing electrical safety.

4. Sheath outer sheath

The outermost layer of the overall cable is wrapped with a thermoplastic sheath layer, usually white, but there are also special black, blue, purple or yellow PVC materials for special purposes. The outer sheath provides mechanical protection, wear resistance, corrosion resistance, and other functions. Different colored sheaths can be used to identify different purposes or system circuits.

3, Types of electrical cable tps

electrical cable tps can be classified based on multiple dimensions such as structure, number of cores, color, and specifications

3.1 Classification by number of conductor cores

| type | describe | Common applications |

| Single core TPS cable | Only containing one copper conductor | Control circuits, grounding wires, etc |

| twin active tps cable | Live wire and neutral wire | Lighting, general power lines |

| Twin+Earth tps cable | Two conductors plus a copper ground wire | Standard wiring for home circuits |

| 3 core tps cable | Three insulated conductors | Three phase electric or two-phase+ground circuit |

3.2 Classification based on the shape of the outer sheath of TPS Wire

Flat TPS cable: commonly used for threading pipes inside walls, easy to wire.

Circular TPS cable: suitable for environments with higher current and intensity.

3.3 Classification by conductor type

Solid conductor: Strong rigidity, not suitable for repeated bending.

Stranded conductors: They have good flexibility and are easy to install.

4, The meaning of TPS cables in common colors

The color of the outer sheath of TPS cable is not just decoration, they usually have specific meanings in the electrical industry. Although there may be slight differences in standards among countries or regions, taking Australia as an example, common colors are roughly as follows:

White TPS cable: commonly used in lighting circuits and is the most common color for residential cables.

Black TPS cable: commonly used for socket circuits or main power supply circuits.

Blue TPS cable: Generally used for weak current systems or alarm systems.

Yellow TPS cable: may represent special circuits such as solar or backup power.

Purple TPS cable: may represent communication or data cabling systems, and is also used to distinguish certain specialized lines.

5, Technical parameters of TPS cable

| Item | Indicator Description |

| rated voltage | 450/750V |

| operation temperature | -15 ℃ to+70 ℃ (usually limited by PVC sheath) |

| Core count range | 1-5 cores (commonly 2 core tps wire, 3 core tps wire) |

| Range of cross-sectional area | TPS cable 1.0mm ² to TPS cable 16mm ² |

| standard specification | AS/NZS 5000.2 |

| Flame retardant performance | Meets the IEC 60332 standard |

6, TPS Cable Standards and Certification

In Australia and New Zealand, TPS cables must comply with the following standards:

AS/NZS 5000.2: Suitable for 450/750V PVC insulated and sheathed cables.

AS/NZS 3808: There are specific regulations for testing the electrical and thermal performance of cables.

AS/NZS 3000 (Electrical Wiring Rules): specifies the wiring method, safety protection distance, maximum current carrying capacity and other parameters of TPS cable.

In addition, all cables sold in Australia must also pass the Regulatory Compliance Mark certification to ensure compliance with electrical safety and EMC requirements.

7, Application areas of flat sheathed tps cables

TPS cables are mainly used in low-voltage distribution systems, with specific application scenarios including:

1. Residential buildings

TPS cables are widely used for wiring circuits such as lighting, sockets, kitchen appliances, and air conditioning in residential homes. Its flat structure is suitable for concealed wiring in gypsum board walls and ceilings.

2. Commercial buildings

TPS cables are commonly used for wiring in the internal electrical systems of office buildings, shopping malls, catering establishments, and other places. Due to their compact structure, neat wiring, and low failure rate, they are highly favored by electrical contractors.

3. Schools and hospitals

These places have extremely high requirements for electrical safety, and TPS cables are widely used in low voltage power supply lines on teaching and ward floors due to their excellent insulation and moderate anti-interference performance.

4. Temporary buildings and equipment

TPS cable are also commonly used in temporary buildings, temporary distribution boxes, mobile homes, and container houses. They are quick to install, easy to dismantle, and suitable for short-term electrical system construction.

8, TPS cable specific model and application table

The model of TPS cable is usually distinguished by "number of cores+cross-section+voltage level". Here are several common models and application scenarios:

| model | CORE | Cross sectional area (mm ²) | rated voltage | Application scenarios |

| 1.5 mm 2c e tps cable | 2-core+ground wire | 1.5 | 450/750V | Ordinary lighting circuit |

| 2.5 mm 2c e tps | 2-core+ground wire | 2.5 | 450/750V | Socket circuit, electric water heater |

| 2.5 mm 3c e tps | 3-core+ground wire | 2.5 | 450/750V | Three phase electrical appliances, small power equipment |

| 4 mm 2c e tps cable | 2-core+ground wire | 4 | 450/750V | Air conditioning, high-power electrical appliances |

| 3C+E 4mm² TPS cable | 3-core+ground wire | 4 | 450/750V | Three phase motors, garage doors, etc |

| 2C 1.0mm² TPS cable | 2 core | 1 | 450/750V | Switch control, weak current connection |

| 3C 6.0mm² TPS cable | 3 core | 6 | 450/750V | Industrial power line |

Note: C represents "Core", E represents "Earth", which is the grounding wire.

9, Current carrying capacity of thermoplastic sheathed flat tps cable

The current carrying capacity of TPS cable depends on multiple factors, including the cross-sectional area of the cable conductor, the conductor material (copper or aluminum), the installation method (buried in the wall, laid in the air, through pipes, etc.), the ambient temperature, and the single core or multi-core structure. The following are approximate reference values for current carrying capacity of TPS copper core cables of some common specifications in standard environments (based on the Australian AS/NZS 3008 standard):

The current carrying capacity of TPS cables commonly used in single-phase or three-phase applications (copper conductor, ambient temperature of 25 ° C, exposed installation)

| Cable specifications (square millimeters) | Number of conductors | Installation method | Current carrying capacity (A) |

| 1.0 mm Tps cable | 2 core/3 core | Clear application and tube insertion | 10–13 A |

| 1.5 mm Tps cable | 2 core/3 core | Clear application and tube insertion | 16–18 A |

| 2.5 mm Tps cable | 2 core/3 core | Clear application and tube insertion | 20–24 A |

| 4 mm Tps cable | 2 core/3 core | Clear application and tube insertion | 25–32 A |

| 6 mm Tps cable | 2 core/3 core | Clear application and tube insertion | 32–40 A |

| 10 mm Tps cable | 2 core/3 core | Clear application and tube insertion | 45–55 A |

| 16 mm Tps cable | 2 core/3 core | Clear application and tube insertion | 60–75 A |

10, TPS cable selection and construction precautions

When using TPS cable, the following points should be noted:

1. Confirmation criteria: It is necessary to use products that comply with AS/NZS 5000.2 standards.

2. Rated current: Select the appropriate cross-sectional area based on the load current to avoid overload.

3. Wiring method: It cannot be installed exposed, and must be laid in pipe troughs, walls, and ceilings.

4. Color identification: Strictly identify the phase wire, neutral wire, and grounding wire according to the specifications to avoid misconnection.

5. Bending radius: Avoid excessive bending during installation to prevent damage to the conductor or insulation layer.

6. Do not use in high temperature/underwater/outdoor exposure environments.

T

For flat TPS CABLE is exported to the Australian market, SAA certification is a mandatory requirement.

GERITEL cable's TPS cable has passed the Australian SAA certification, and the conductor and insulation standards comply with the Australian region