Cables play a vital role in the design of modern power and electronic equipment. There are many types of wires and cables, each with its own specific performance and application range. Among the many cable products, TPS wires (Thermoplastic Sheathed Cable), XLPE cables (cross-linked polyethylene cables) and PVC cables (polyvinyl chloride cables) are the most common types. This article will discuss in detail the advantages of TPS wires over XLPE cables and PVC cables, and focus on specific types such as TPS Cable, Flat TPS Cable, Twin Active TPS, and analyze their performance in different application scenarios.

1. What is TPS cable?

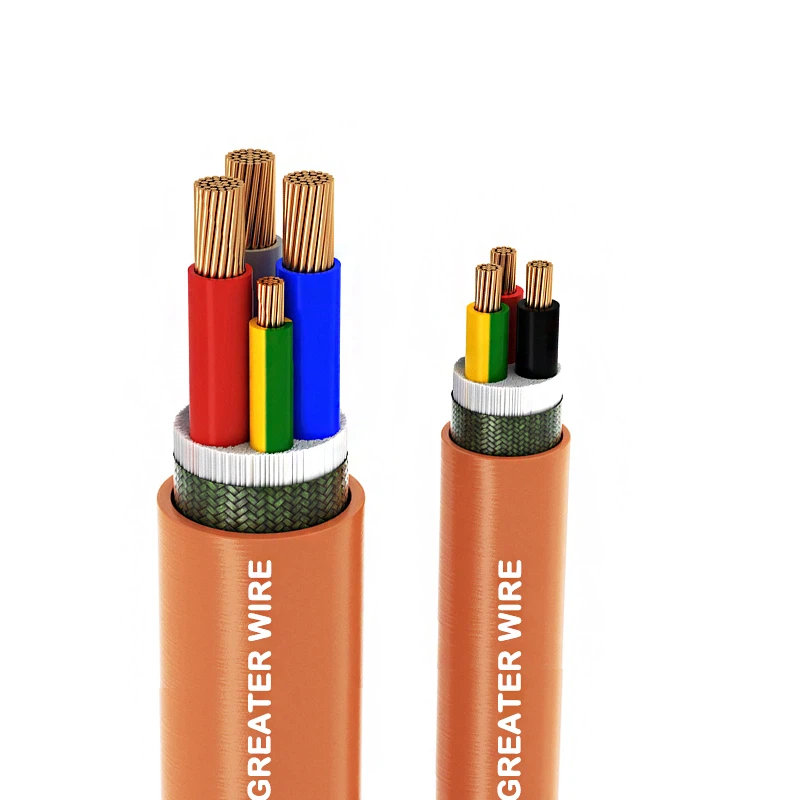

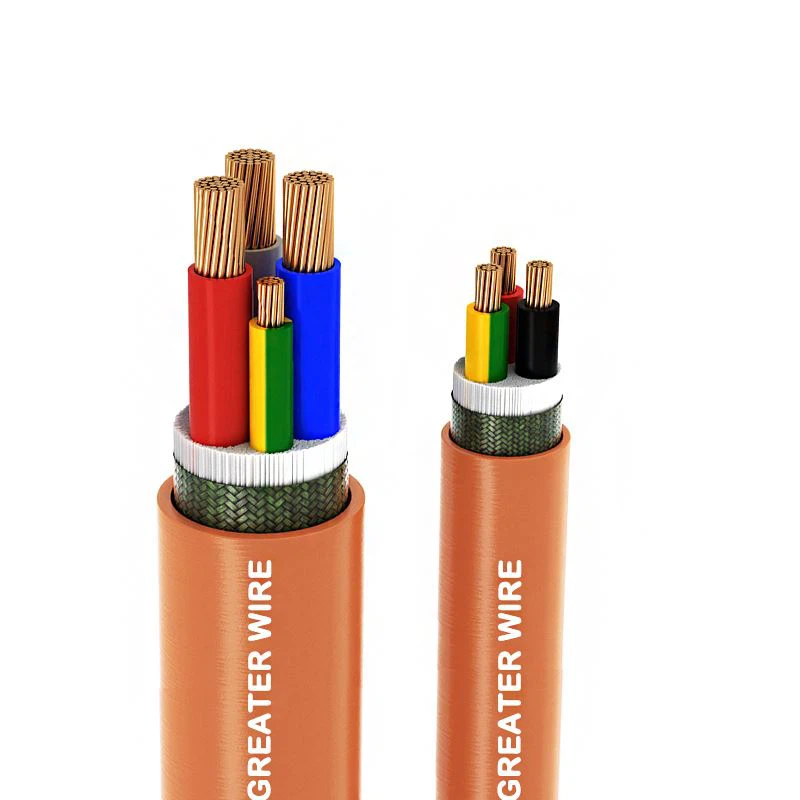

TPS cable is a cable that uses thermoplastics (such as PVC) as sheath and insulation materials. It is usually composed of conductive copper or aluminum wires, and the outer sheath has good flexibility, high temperature resistance and resistance to mechanical damage. TPS wires are commonly used in residential, commercial and industrial fields, and are suitable for electrical connections of low-voltage applications and some light industrial equipment.

1.1 Flat TPS Cable

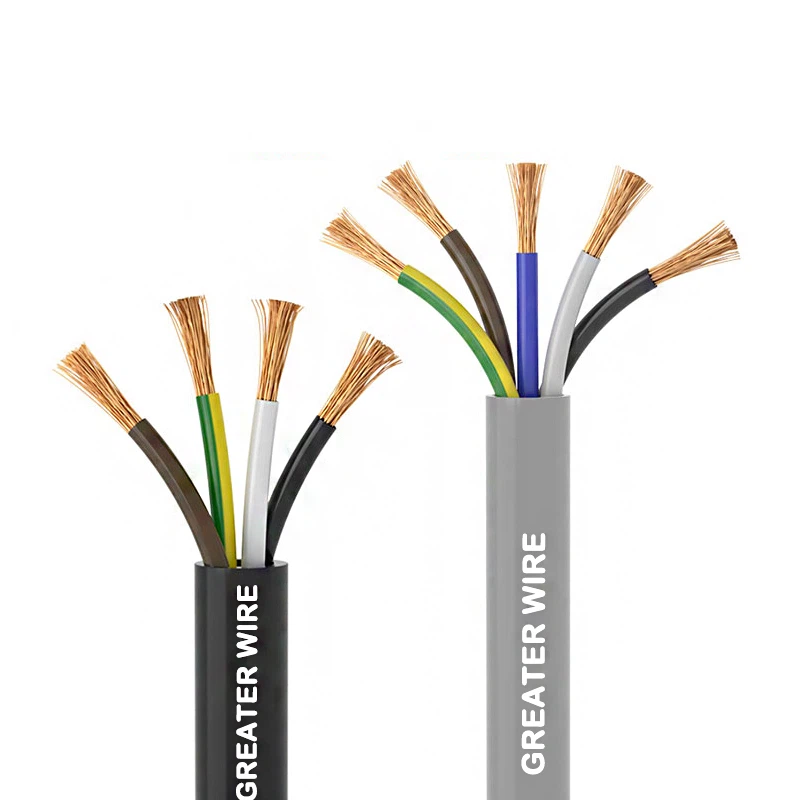

Flat TPS Cable is a specially designed cable type with a flat conductor arrangement. Compared with common round cables, Flat TPS Cable has a more compact structure and is suitable for places with small installation space. Due to its shape, Flat TPS Cable can save installation space more effectively and avoid excessive crossing and twisting during wiring, thereby improving the efficiency of installation.

1.2 Twin Active TPS

Twin Active TPS refers to TPS cables with dual conductors. This type of cable is usually used for equipment or circuits that require bidirectional power supply, such as household appliances, lighting equipment, etc. Due to the dual-conductor design, Twin Active TPS cable can provide positive and negative currents at the same time to meet the needs of dual-circuit electrical systems. Its dual-conductor structure gives the cable a higher load capacity and can distribute current more efficiently, avoiding overheating and power loss.

2. Differences and advantages between TPS wires and XLPE cables and PVC cables

2.1 Differences between TPS wires and XLPE cables

XLPE cables use cross-linked polyethylene (XLPE) as insulation material and are mainly used in medium and high voltage power transmission systems. The cross-linking process of cross-linked polyethylene makes its molecular structure more stable, thus giving the cable excellent heat resistance, voltage resistance and chemical corrosion resistance.

Advantages of TPS wires compared with XLPE cables:

Cost-effectiveness: TPS wires have a relatively low manufacturing cost and are suitable for low-voltage power systems with limited budgets, especially for residential and small commercial purposes. In contrast, XLPE cables have a higher production cost, so they are more used in industrial and high-voltage power systems.

Flexibility: The outer sheath of TPS wires is made of thermoplastic material, which has good flexibility and is easy to install and wire. In particular, Flat TPS Cable can adapt to environments with limited space and avoid excessive space occupation. XLPE cables are slightly inferior in flexibility, especially in low temperature environments, and may become brittle and difficult to bend.

Easy installation: TPS cables are more flexible during installation and are easy to bend and lay. The design of Flat TPS Cable makes cable routing more compact and can fit into small installation spaces. This is very beneficial for electrical wiring in homes and commercial buildings. The installation of XLPE cables is usually more complicated, especially in larger power systems that require more technical support.

Corrosion resistance: Although XLPE cables excel in chemical resistance, the PVC outer sheath of TPS cables also has considerable corrosion resistance and is suitable for humid and corrosive environments.

2.2 Differences between TPS wires and PVC cables

PVC cables refer to cables whose outer sheath and insulation layer are made of polyvinyl chloride (PVC) materials. PVC cables are widely used in low-voltage power and control systems due to their low manufacturing cost and strong corrosion resistance.

Advantages of TPS wires over PVC cables:

High temperature resistance: TPS wires are usually made of thermoplastic materials and can withstand higher operating temperatures, especially in some high temperature environments. PVC cables have a lower operating temperature and are usually not used in high temperature environments.

Tensile strength: The outer sheath of TPS wire has strong tensile strength, which can resist the stretching and extrusion of external forces and is suitable for use in harsh environments. Although PVC cable has good flexibility, its tensile strength is relatively low and it is easily damaged by external forces.

Electrical performance: TPS wire has relatively good electrical performance and is suitable for low-voltage power systems in homes, commerce and light industry. Although PVC cable has a lower cost, it lacks in electrical performance and long-term stability.

2.3 Comprehensive comparison: Advantages of TPS wire

Flexibility and installation convenience: TPS wire has excellent flexibility, especially Flat TPS Cable, whose flat design makes wiring in small spaces easier. In addition, TPS wire is efficient in installation and wiring in conventional environments, and usually does not require complex installation techniques.

Damage resistance: The thermoplastic sheath used in TPS wire provides excellent tensile, impact and friction resistance. Even under high voltage and high load conditions, TPS wire can still maintain good physical properties, especially for construction, industry, home and other occasions.

Corrosion resistance and environmental adaptability: The PVC outer sheath of TPS wire can effectively resist chemical corrosion, so it is suitable for use in humid and corrosive environments, such as underground pipelines, humid areas, and chemical plants. Although PVC cables also have certain corrosion resistance, they may not be as good as TPS cables in some harsh environments.

Cost advantage: Under the same working conditions, the cost of TPS wires is generally lower than that of XLPE cables, and compared with PVC cables, they are also more advantageous in terms of high temperature resistance and tensile strength. For application scenarios with limited budgets and certain performance requirements, TPS cables are undoubtedly a very attractive choice.

3. Advantages of TPS wires in practical applications

Application in residential and commercial buildings: Due to the good flexibility and cost-effectiveness of TPS wires, it is widely used in electrical systems in residential and commercial buildings. Whether it is power transmission, lighting wiring or low-voltage signal transmission, TPS cables can provide reliable performance. Especially in space-constrained environments, Flat TPS Cable can greatly save installation space.

Application in the industrial field: Although XLPE cables have certain advantages in high-temperature and high-voltage power systems, TPS wires also perform well in industrial control systems, equipment connections, and power distribution systems. Its corrosion resistance and mechanical damage resistance make it widely used in industrial environments, especially in places that require durable and flexible installation.

Home appliance connection: Twin Active TPS cable is a dual-conductor cable suitable for dual-circuit power supply of power and control signals in home appliances. Its design not only improves the efficiency of current transmission, but also reduces power loss and the risk of damage to electrical equipment.