Electrical wiring plays a vital role in powering various systems, whether in residential, commercial, or industrial settings. Among the many types of wires available, TFFN cable has gained popularity for its versatility and efficiency in specific applications. This article dives into the meaning of TFFN wire, its main features, and the benefits it brings to electrical installations, using TFFN wire and wire TFFN as key terms throughout.

Definition of TFFN Cable

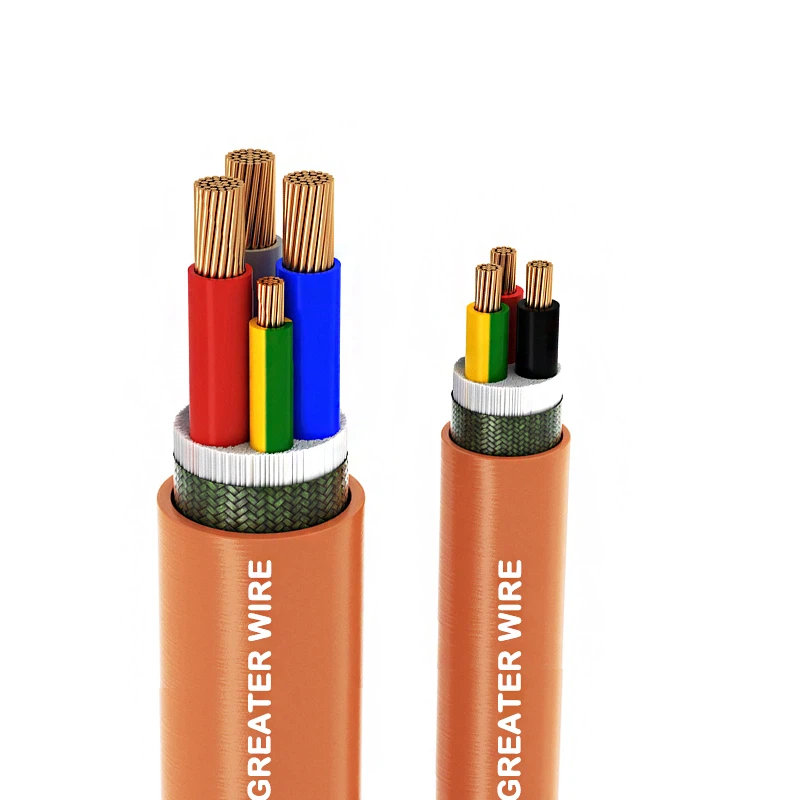

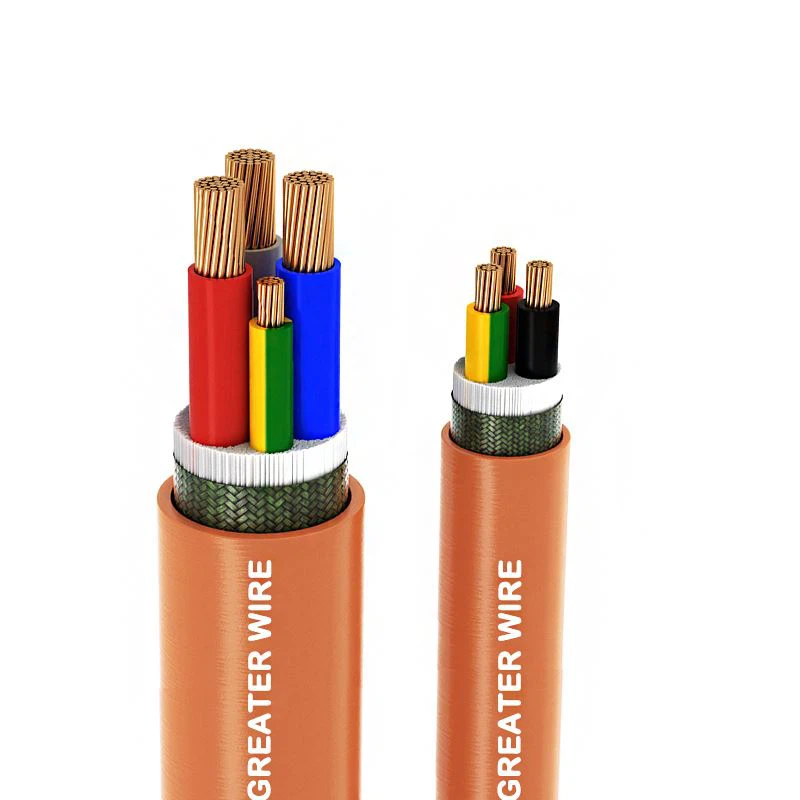

TFFN cable stands for Thermoplastic Flexible Fixture Nylon cable. It is a lightweight, single-conductor electrical wire made up of the following components:

Copper Conductor:

Typically a stranded conductor to provide flexibility.

Ensures excellent conductivity and low electrical resistance.

PVC Insulation:

A thermoplastic layer that offers electrical insulation and heat resistance.

Nylon Jacket:

A durable nylon coating that enhances the wire's abrasion resistance and protects it from moisture and chemicals.

TFFN wire is widely used in indoor electrical applications, including light fixtures, appliances, and control circuits, thanks to its lightweight and flexible design.

Main Features of TFFN Cable

TFFN cable stands out for its unique set of features that make it suitable for various electrical installations. Below is an in-depth look at its main features:

High Temperature Tolerance:

TFFN wire is rated for 90°C (194°F) in dry locations, making it suitable for environments where heat resistance is required.

In damp environments, it is rated for 75°C (167°F).

Voltage Rating:

TFFN wire is designed to operate at up to 600 volts, making it appropriate for most residential, commercial, and industrial wiring tasks.

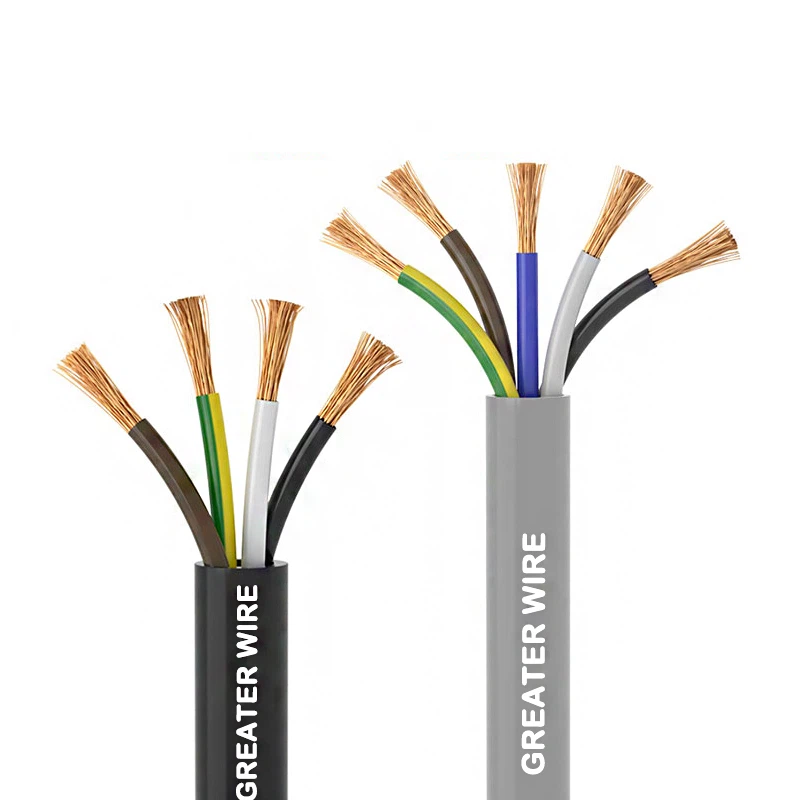

Flexibility:

The stranded copper conductor and lightweight design make TFFN cable highly flexible, allowing for easy installation in tight spaces or intricate electrical setups.

Durability:

The PVC insulation provides protection against wear and tear.

The nylon jacket adds resistance to abrasion, chemicals, and moisture, ensuring a long lifespan in appropriate conditions.

Lightweight Construction:

TFFN cable is thinner and lighter than many other wires, reducing installation complexity and costs.

Color Options:

Available in a range of colors, TFFN wire simplifies circuit identification and organization during installations.

Applications of TFFN Wire

The features of TFFN wire make it an excellent choice for specific applications. Common uses include:

Lighting Fixtures:

Its heat-resistant properties make it ideal for light fixture wiring, where temperatures can rise due to enclosed spaces and bulb heat.

Control Circuits:

TFFN wire's flexibility allows it to be used in control panels and circuits that require precise routing.

Appliances:

Frequently used in appliances that demand durable and heat-resistant wiring.

Conduit Installations:

Installed within conduits in dry or damp locations to provide added protection from physical and environmental damage.

Comparison with Other Wire Types

To better understand TFFN cable's role, it's helpful to compare it with other common wire types:

TFFN vs. THHN:

THHN (Thermoplastic High Heat Nylon) wire shares similar construction to TFFN but has additional ratings for oil resistance and outdoor use.

TFFN is better suited for light-duty, indoor applications, while THHN offers more versatility for demanding environments.

TFFN vs. UF-B:

UF-B (Underground Feeder Cable) is designed for direct burial and outdoor use without a conduit.

TFFN cable, in contrast, must be installed in a protective conduit when used in damp locations.

TFFN vs. XHHW:

XHHW (Cross-linked High Heat Water-resistant) wire offers superior moisture and heat resistance, making it ideal for industrial and outdoor applications.

TFFN is more economical and appropriate for indoor, less demanding environments.

Advantages of TFFN Wire

Using TFFN wire offers several benefits:

Cost-Effectiveness:

Its lightweight design and material efficiency make TFFN wire more affordable than heavier-duty options like XHHW or UF-B.

Ease of Installation:

Flexibility and color options simplify routing, identification, and circuit organization.

Versatility:

Suitable for a variety of indoor applications, including light fixtures, appliances, and control panels.

Durability in the Right Conditions:

The nylon jacket protects against abrasion and chemical exposure, ensuring long-lasting performance.

Limitations of TFFN Wire

Despite its many advantages, TFFN wire has some limitations:

Outdoor Use:

TFFN wire is not UV-resistant and is unsuitable for prolonged exposure to sunlight unless housed in a conduit.

Direct Burial:

The insulation and jacket are not designed for direct burial. Protective conduits are required for underground installations.

Abrasion Resistance:

While the nylon jacket adds durability, it may not suffice in highly abrasive environments without additional protection.

Safety Standards and Compliance

TFFN cable is compliant with key safety and industry standards:

UL Listing:

TFFN wire is certified by Underwriters Laboratories (UL), ensuring its safety and reliability.

NEC Compliance:

It meets the requirements of the National Electrical Code (NEC) for use in dry and damp locations when properly installed.

Best Practices for Using TFFN Wire

To maximize the benefits of TFFN wire, consider the following best practices:

Choose the Right Environment:

Use TFFN wire in indoor applications or within conduits for damp locations.

Protect with Conduits:

Install TFFN wire in a conduit to provide additional protection against physical damage and environmental exposure.

Inspect Before Installation:

Ensure the wire is free of damage or defects before installation to avoid potential hazards.

Adhere to Electrical Codes:

Follow local and national electrical codes to ensure safe and compliant installations.