Electrical wires and cables are fundamental components of any electrical system, and their construction determines how well they perform under different conditions. Among these, TFFN wire is a versatile and widely used type of cable known for its flexibility and durability in specific applications. This article explains how TFFN wire is constructed, explores the materials and manufacturing process, and highlights its unique features. Throughout, we will use the keywords TFFN wire and wire TFFN to provide comprehensive insights.

What is TFFN Wire?

TFFN stands for Thermoplastic Flexible Fixture Nylon, and the name reflects its key properties:

Thermoplastic Insulation: A heat-resistant layer that protects the wire from electrical leakage and environmental factors.

Flexible Conductor: The copper conductor is stranded for added flexibility, making it easy to install in tight spaces.

Fixture Wire: Designed for use in light fixtures, appliances, and control circuits.

Nylon Jacket: An additional layer of protection that enhances the wire's resistance to abrasion, chemicals, and moisture.

Core Components of TFFN Wire

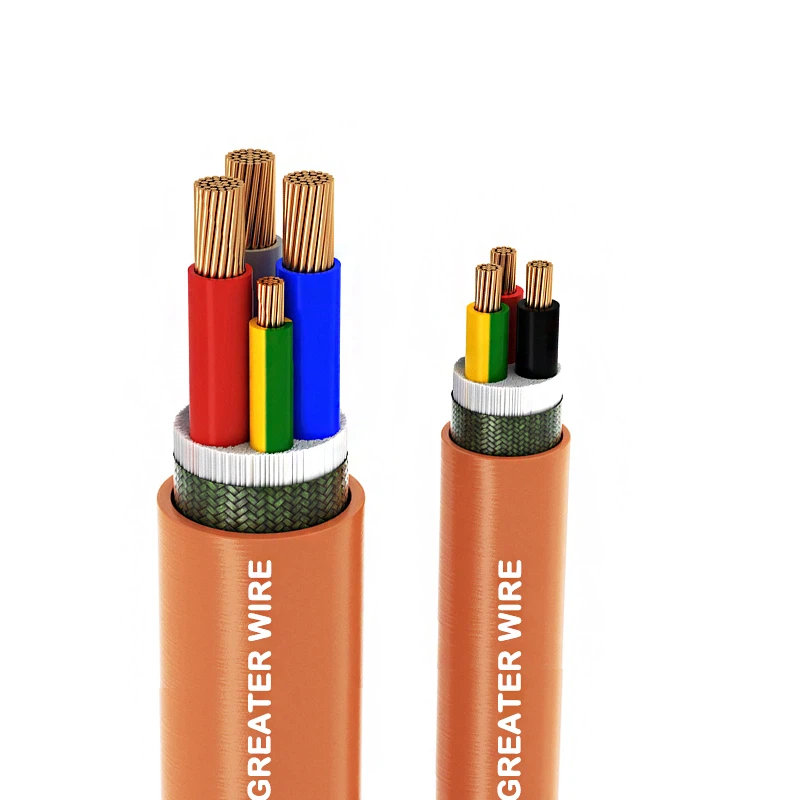

To understand how TFFN wire is constructed, it's important to explore its three main components:

Copper Conductor:

Material: Copper is the most commonly used material for TFFN wire due to its excellent electrical conductivity and flexibility.

Construction: The conductor is stranded, meaning it is composed of multiple small copper strands twisted together. This design improves flexibility compared to solid-core conductors.

Thermoplastic Insulation:

Material: Polyvinyl chloride (PVC) is used as the primary insulation material. PVC provides electrical isolation and resistance to heat and moisture.

Thickness: The insulation layer is designed to meet specific safety standards while maintaining the wire's flexibility.

Nylon Jacket:

Material: A nylon outer layer adds abrasion and chemical resistance, ensuring durability in challenging environments.

Purpose: The nylon jacket also protects the PVC insulation from damage during installation and use.

Step-by-Step Construction of TFFN Wire

The manufacturing process for wire TFFN involves several steps to ensure the wire meets industry standards and performs reliably:

Copper Refinement:

The process begins with high-purity copper, which is melted and formed into thin rods.

These rods are drawn through dies to produce strands of the desired diameter.

Stranding:

The copper strands are twisted together to create a stranded conductor. The stranding process determines the wire's flexibility and current-carrying capacity.

Insulation Application:

The stranded conductor is coated with PVC insulation through an extrusion process.

The PVC layer is uniformly applied to provide consistent insulation and ensure safety under various conditions.

Nylon Coating:

After the PVC insulation is applied, the wire passes through a second extrusion process to add the nylon jacket.

The nylon coating adheres tightly to the PVC insulation, forming a seamless protective layer.

Testing and Quality Control:

Each wire undergoes rigorous testing for electrical resistance, insulation integrity, and physical durability.

Compliance with standards such as UL (Underwriters Laboratories) and the NEC (National Electrical Code) is verified.

Cutting and Packaging:

The finished wire is cut to standard lengths and spooled for distribution.

Unique Features of TFFN Wire Construction

The specific design and construction of TFFN wire give it several distinct features:

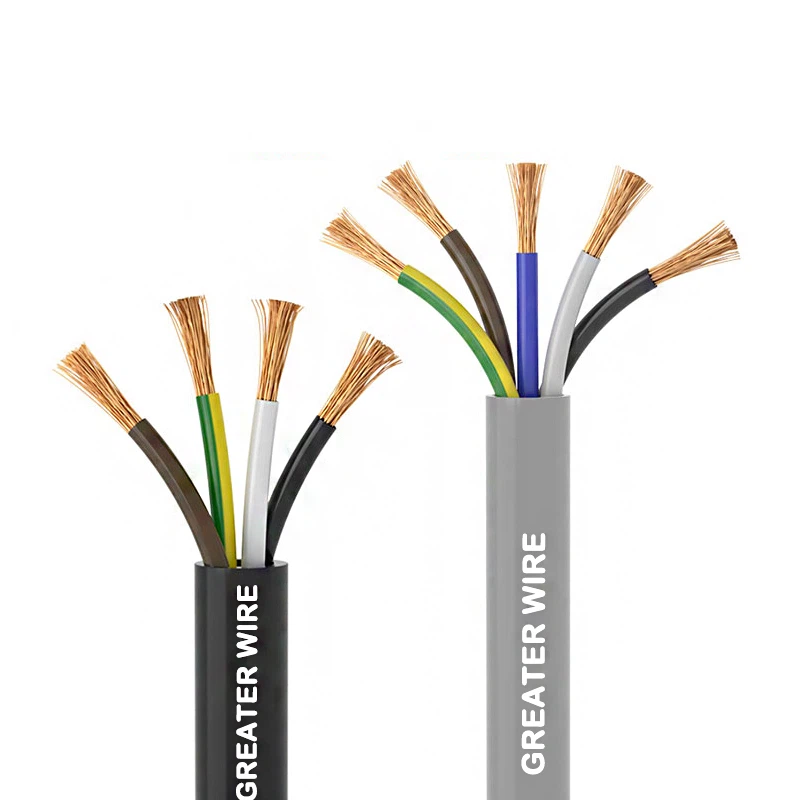

Flexibility:

The stranded copper conductor and thin insulation layers make TFFN wire easy to bend and maneuver, even in tight spaces.

Heat Resistance:

The PVC insulation allows the wire to handle temperatures of up to 90°C (194°F) in dry environments and 75°C (167°F) in damp conditions.

Lightweight:

TFFN wire is thinner and lighter than many other wire types, simplifying transportation and installation.

Durability:

The nylon jacket provides additional protection against abrasion, chemicals, and moisture, extending the wire's lifespan.

Customizability:

TFFN wire is available in various colors for easy circuit identification, as well as different gauges to meet specific electrical needs.

Applications of TFFN Wire

The construction of TFFN wire makes it ideal for several applications:

Light Fixtures:

Its heat-resistant and flexible design makes it perfect for wiring in light fixtures and other enclosed spaces.

Control Circuits:

TFFN wire is commonly used in control panels, where its flexibility simplifies routing through complex configurations.

Conduit Installations:

When installed inside conduits, TFFN wire is protected from physical damage and is suitable for dry and damp locations.

Appliances:

Its durable and lightweight nature makes it ideal for internal wiring in household and commercial appliances.

Comparison with Other Wires

To better understand the value of TFFN wire, let's compare it to other wire types:

THHN Wire:

Similar in construction but has additional features for outdoor use and oil resistance.

TFFN wire is more flexible and suited for light-duty indoor applications.

XHHW Wire:

Designed for extreme environments, with cross-linked polyethylene insulation providing superior water and heat resistance.

TFFN wire is more economical for standard indoor applications.

MTW Wire:

MTW (Machine Tool Wire) shares TFFN's flexibility but is specifically designed for industrial equipment wiring.

TFFN wire is more versatile for residential and commercial use.

Advantages of TFFN Wire Construction

The thoughtful construction of TFFN wire provides several benefits:

Ease of Installation:

Lightweight and flexible, TFFN wire is easy to handle and install, even in complex setups.

Enhanced Safety:

The dual-layer protection (PVC insulation and nylon jacket) ensures electrical safety and reduces the risk of shorts or electrical leakage.

Long Lifespan:

The durable construction minimizes wear and tear, making TFFN wire a cost-effective choice for long-term use.

Compliance with Standards:

The construction process ensures that TFFN wire meets all relevant safety and performance standards.

Challenges and Limitations

Despite its many advantages, TFFN wire does have some limitations:

Limited Outdoor Use:

TFFN wire is not UV-resistant and must be installed in a conduit for outdoor or damp locations.

Direct Burial Restrictions:

It cannot be buried directly without additional protection, limiting its use in underground installations.

Abrasion Resistance:

While the nylon jacket provides protection, it may not be sufficient for extremely abrasive environments.