In electrical and construction engineering, the selection of cables is critical to the safety, efficiency, and durability of the system. THWN cable (Thermoplastic Heat and Water-resistant Nylon-coated) is a cable with excellent heat resistance, water resistance, and chemical corrosion resistance, and is widely used in various environments. Due to its unique properties, THWN cable is particularly suitable for wet or humid environments. This article will explore the environments where THWN cable is suitable, help users better understand its characteristics, and provide a reference for electrical installation.

1. Basic definition and characteristics of THWN cable

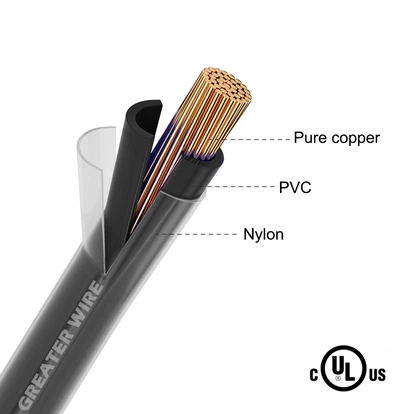

THWN cable is a water-resistant and heat-resistant cable. Its outer layer is usually coated with nylon, which not only enhances the cable's water resistance, but also provides better abrasion resistance and chemical corrosion resistance. THWN cable can operate normally at a maximum temperature of 90°C and is resistant to water, moisture and common chemicals. Therefore, it is very suitable for electrical applications that require water resistance, moisture resistance and corrosion resistance.

2. Main application environment of THWN cable

THWN cable is widely used in various environments due to its waterproof, high temperature, abrasion and chemical corrosion resistance. The following are some typical application scenarios:

Wet environment

One of the biggest features of THWN cable is its water resistance. Its nylon outer coating can effectively prevent moisture from entering the cable, so it is suitable for power transmission in wet, underground or near water sources. Whether in underground cable laying or in facilities such as water treatment plants or power pumping stations, THWN cable can provide excellent waterproof performance to ensure the stable operation of the power system.

For example, THWN cables are often used to connect water pumps or drainage equipment, as these devices are often exposed to wet environments. Using THWN cables can effectively reduce the occurrence of electrical failures and ensure the long-term stable operation of equipment.

Underground power wiring

Due to its excellent water resistance, THWN cables are very suitable for underground power wiring. In urban infrastructure and industrial parks, underground power distribution systems are a common way of distributing electricity. Cables are usually buried in the soil and face water intrusion, soil corrosion and other external pressures. In this environment, choosing THWN cables can effectively avoid water infiltration and moisture effects and extend the service life of the cables.

Especially in underground power grids, THWN cables can ensure that the power supply system works stably under harsh conditions and avoid electrical failures caused by water intrusion.

Chemical corrosion environment

In addition to water resistance, the nylon coating of THWN cables also has strong resistance to chemical corrosion and can withstand erosion by oil, gasoline and other chemicals. Therefore, it is suitable for some environments that may be exposed to corrosive liquids or gases, such as chemical plants, oil and gas extraction or chemical storage facilities.

In these places, the use of THWN cables can ensure that the power system is not affected by chemicals and avoid the failure of the cable insulation layer due to corrosion, thereby improving the safety and reliability of the system.

Outdoor electrical systems

In outdoor electrical systems, cables are often exposed to harsh climatic conditions, including rain, moisture, and ultraviolet rays. THWN cables are particularly suitable for outdoor power distribution systems due to their water resistance and good external protective layer. Whether in street power distribution or in applications such as garden lighting and external equipment connection, THWN cables can provide sufficient protection to prevent electrical failures caused by environmental factors.

For example, in outdoor landscape lighting systems, the use of THWN cables can effectively ensure that electrical equipment can still work stably when exposed to rain and humid environments for a long time.

Agricultural and horticultural facilities

In the fields of agriculture and horticulture, THWN cables also play an important role. Electrical facilities in these fields are often exposed to environments with heavy moisture, such as irrigation systems, greenhouse lighting, temperature control equipment, etc. The water-resistant and corrosion-resistant properties of THWN cables make them the preferred cables for electrical installations in these facilities, and they can effectively protect the power system from moisture and chemical corrosion.

Application in high temperature environments

In addition to water resistance, THWN cables also have good high temperature resistance and can withstand operating temperatures up to 90°C. Therefore, it is also suitable for some environments with higher temperatures, such as industrial manufacturing plants, power stations, etc. These places may generate high heat, so cables that can withstand high temperatures are required to avoid cable damage or fire accidents caused by high temperatures.

3. Comparison of THWN cables: THHN cables and THWN cables

Although THWN cables and THHN cables (Thermoplastic High Heat-resistant Nylon-coated wire) both have nylon coatings and look similar in appearance, there are significant differences in their application environments. THHN cables are mainly designed for dry environments and are suitable for those with higher temperatures, without the water resistance of THWN cables. THHN cables are commonly used in indoor electrical systems, such as power wiring in homes and commercial buildings. In wet or humid environments, THHN cables perform poorly and are prone to short circuits or electrical failures due to moisture penetration.