1. Understanding XHHW Wire: Composition and Key Features

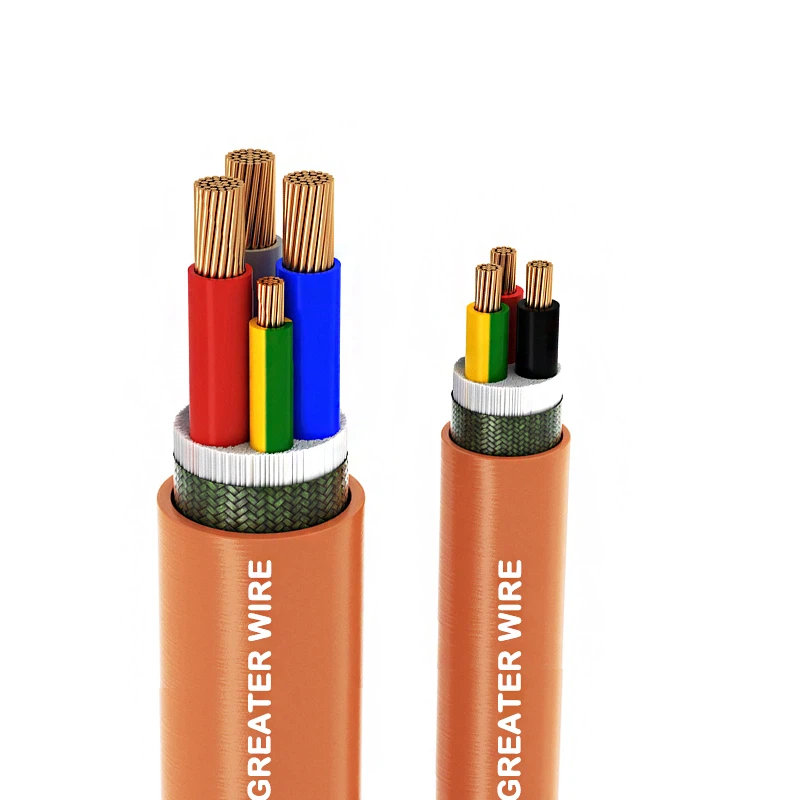

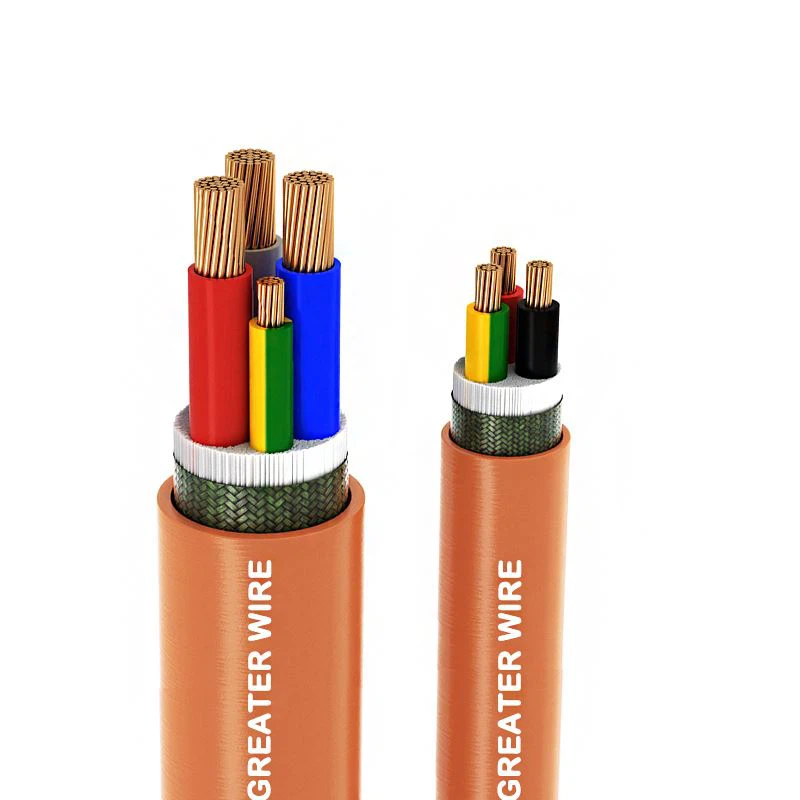

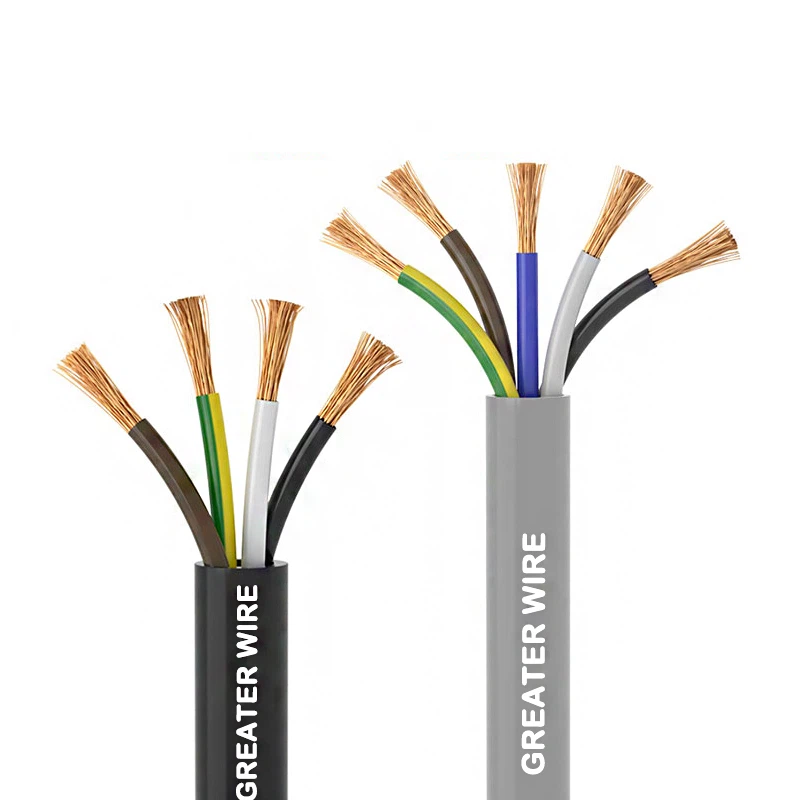

XHHW (Cross-Linked Polyethylene High Heat- and Water-Resistant) wire is engineered for reliability in demanding conditions. Its construction includes:

Conductor: High-purity copper (e.g., XHHW-2 copper wire) ensures excellent conductivity and corrosion resistance.

Insulation: Cross-linked polyethylene (XLPE) provides thermal stability up to 90°C in wet or dry environments.

Jacketing: A protective outer layer enhances abrasion and moisture resistance.

The XHHW-2 designation signifies a dual-layer insulation system, rated for higher voltage applications like XHHW-2 1000V and XHHW-2 600V. This design is critical for mitigating risks posed by humidity.

2. Extreme Humidity and Electrical Wiring: Risks and Challenges

Humidity introduces two primary threats to wiring:

Moisture Ingress: Water penetration can lead to short circuits, insulation breakdown, and corrosion.

Thermal Stress: High humidity combined with temperature fluctuations accelerates material degradation.

Conventional wires often fail under these conditions, but XHHW's XLPE insulation and tight molecular structure prevent water absorption. For example, XHHW 4AWG-a thicker gauge ideal for high-current applications-retains its dielectric strength even in 100% relative humidity environments.

3. How XHHW Wire Resists Humidity: Material Science in Action

A. Cross-Linked Polyethylene (XLPE) Insulation

XLPE undergoes a chemical process that creates covalent bonds between polymer chains, resulting in:

Low Permeability: Minimal water vapor transmission, even in prolonged exposure.

Thermal Endurance: Maintains flexibility and insulation properties from -40°C to 90°C.

B. Copper Conductors: Built for Corrosion Resistance

The XHHW-2 copper wire leverages copper's innate resistance to oxidation. Unlike aluminum, copper does not form resistive oxide layers when exposed to moisture, ensuring stable conductivity over decades.

C. Dual Insulation in XHHW-2 Variants

The XHHW-2 1000V and XHHW-2 600V cables feature an additional insulation layer, creating a redundant barrier against moisture. This design is certified for use in wet locations by the National Electrical Code (NEC), making it ideal for outdoor installations, underground conduits, and industrial facilities.

4. Performance Metrics: Testing XHHW in Humid Conditions

Independent studies and industry certifications validate XHHW's humidity resilience:

UL 44/83 Standards: Require wires to withstand 14 days of submersion in water without insulation failure.

Dielectric Strength Testing: XHHW-2 600V maintains >30 megohms resistance after 1,000 hours in 85% humidity.

Ampacity Retention: XHHW 4AWG shows less than 5% current-carrying capacity loss in humid environments compared to dry conditions.

These metrics underscore why XHHW outperforms THHN, THWN, and other common alternatives in moisture-prone settings.

5. Applications: Where XHHW Shines in High-Humidity Environments

XHHW's humidity resistance makes it indispensable for:

Industrial Facilities: Chemical plants, paper mills, and wastewater treatment centers.

Outdoor Installations: Solar farms, HVAC systems, and marina wiring.

Commercial Buildings: Parking garages, refrigeration units, and data centers.

Case studies highlight XHHW-2 1000V's use in tropical regions, where humidity levels exceed 90% year-round, with zero reported insulation failures over 10+ years.

6. Advantages Over Competing Wire Types

Compared to THHN or PVC-insulated wires, XHHW offers:

Longer Lifespan: XLPE resists embrittlement and cracking.

Higher Temperature Ratings: Safe operation in hotter, wetter environments.

Lower Maintenance Costs: Reduced risk of downtime due to moisture damage.

For heavy-duty applications, XHHW 4AWG provides unmatched current capacity (e.g., 85 amps at 75°C) without derating in humid air.

7. Choosing the Right XHHW Product

Selecting the optimal XHHW wire depends on voltage, gauge, and environment:

XHHW-2 1000V: Ideal for high-voltage industrial machinery.

XHHW-2 600V: Cost-effective for commercial building mains.

XHHW 4AWG: Perfect for feeders, subpanels, and motor circuits.

Always verify NEC and local code compliance for wet/damp location approvals.

8. Future Innovations in Moisture-Resistant Wiring

Emerging technologies, such as nano-coated XLPE and smart moisture sensors, promise to enhance XHHW's capabilities further. However, the core principles of XLPE insulation and copper conductivity will remain foundational.

When you are looking for a reliable cable supplier in the US market, Dongguan Greater Wire & Cable Co., Ltd. is definitely your best choice. Our production scale is constantly expanding, and the new production line is about to be put into use, which will increase the production capacity by another 8%. The R&D team continues to innovate and has obtained a number of technical patents. The company's products have UL83, UL44, UL719, UL493 UL1277 and other certifications, among which XHHW WIRE has excellent high temperature resistance. In terms of price, we rely on our cost control advantage to provide American customers with very attractive quotations to help your project go smoothly.